Roof Supporting System

Roof Supporting System Specification

- Automation Grade

- Manual

- Pressure Ratings

- Up to 250 bar

- Features

- Easy Installation, Adjustable, High Load Bearing

- Surface Treatment

- Galvanized

- Load Capacity

- Up to 30 Tons

- Used For

- Roof and Wall Support

- Operating Temperature

- -20C to 60C

- Power Source

- Manual/Mechanical

- Material

- Mild Steel, Hot Dip Galvanized Steel

- Style

- Modular, Customized

- Properties

- Corrosion Resistant, High Strength

- Capacity

- Up to 30 Tons

- Power

- Manual/Mechanical

- Condition

- New

- Application

- Mining, Tunnels, Underground Construction

- Finish

- Anti-Rust Coated or Zinc Plated

- Maintenance

- Minimal Maintenance Required

- Shape

- C-Channel / I-Beam / Customized

- Accessories

- Anchor Bolts, Base Plates, Fasteners Provided

- Connection Type

- Bolt Connected / Welded as per Requirement

- Compliance

- Meets IS / ASTM Standards

- Dimensions

- As per Order Specification

- Weight

- Depends on Size and Configuration

- Height Adjustment

- Adjustable up to 500 mm

- Safety Standard

- Safety Tested and Certified

Roof Supporting System Trade Information

- Minimum Order Quantity

- 100 Number

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Roof Supporting System

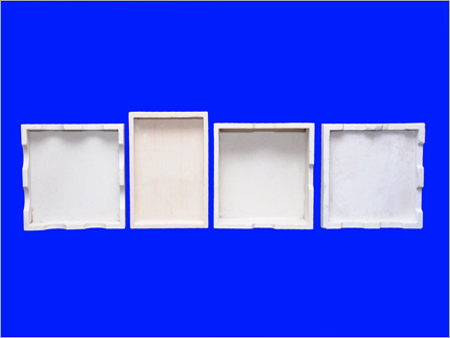

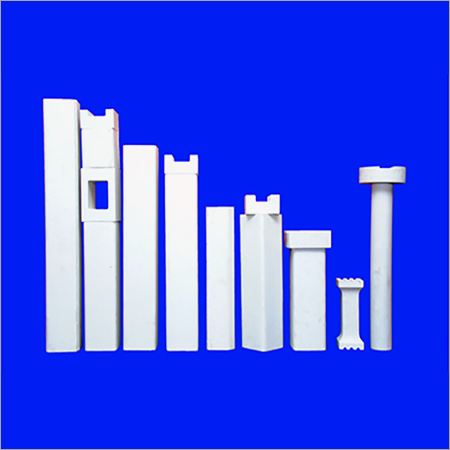

Roof Supporting System is designed as a Kiln Furniture to be used to support for extruded as well as pressed batts. It is designed employing advanced semi-dry pressing method. In addition, it can also be developed using plastic-pressing or casting processes. It provides optimum support to roof with its properties of resisting to thermal shocks. It is also ideal to provide excellent performance in kiln during firing at very high temperatures.

Features of Roof Supporting System:

- Excellent heating as well as cooling rates

- Energy saving design that ensures to save money

- Minimum thermal conductivity between the support as well as material

- Outstanding homogeneity of temperature

Versatile Structural Support

Designed for a range of underground and construction applications, our system offers customized solutions in C-Channel, I-Beam, or tailor-made configurations. Modular design ensures easy adaptation to unique site demands, making it suitable for mining, tunneling, and more.

Superior Durability and Safety

Constructed from high-grade steel and finished with anti-rust or zinc coatings, our roof supports are rigorously tested and certified for safety. Their corrosion resistance and load capacity of up to 30 tons ensure reliable long-term performance, even under harsh conditions.

Effortless Installation and Minimal Maintenance

Our systems are designed for easy installation with manual or mechanical power. All essential accessories are included, and their modular configuration allows for quick adjustments. Minimal maintenance combined with high load bearing capacity reduces downtime and ensures efficiency on the job site.

FAQs of Roof Supporting System:

Q: How is the roof supporting system installed onsite?

A: The system is designed for straightforward installation using either bolted or welded connections, according to your requirements. All necessary accessories like anchor bolts, base plates, and fasteners are provided to facilitate a quick and secure installation process.Q: What makes the system suitable for harsh underground environments?

A: Manufactured from mild or hot dip galvanized steel and treated with anti-rust or zinc plating, the system resists corrosion even in wet or chemically aggressive underground spaces, guaranteeing longevity and reliable strength.Q: When should I choose a C-Channel versus an I-Beam or a customized support?

A: The choice depends on your application and load requirements. C-Channels are preferred for lighter loads or confined spaces, while I-Beams offer superior load-bearing for heavy-duty use. Customized supports are available for unique structural needs.Q: Where can this roof supporting system be utilized?

A: Our system is ideal for mining, tunneling, and other underground construction projects. Its also applicable for providing roof and wall support in a variety of industrial settings requiring strong and adjustable structures.Q: What benefits does the adjustable height feature provide?

A: With adjustability up to 500 mm, the system can be adapted to various ceiling heights or uneven surfaces, ensuring optimal fit and stability in any working condition.Q: How does this product ensure safety and regulatory compliance?

A: Each unit is safety tested and certified, adhering to IS and ASTM standards. This ensures that the product meets strict industrial safety and performance requirements, guaranteeing both regulatory compliance and operator safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Extruded Batts Category

Kiln Furniture

Minimum Order Quantity : 100

Used For : Supporting wares during firing in hightemperature kilns

Load Capacity : Tailored as per design requirement

Surface Treatment : Smooth, Glazed, or as specified

Features : Excellent durability, Long service life, Precise tolerances

Style : Rectangular / Custom shapes

Saggar Tray

Minimum Order Quantity : 100

Used For : Firing and Sintering Ceramic Articles

Load Capacity : Supports Heavy Loads

Surface Treatment : Smooth Finish

Features : Long Life, EcoFriendly, Reusable

Style : Rectangular

Refractory Collar

Minimum Order Quantity : 100

Used For : Sealing, jointing, and insulating hightemperature pipes and ducting

Load Capacity : Varies as per size and installation

Surface Treatment : Natural finish or as requested

Features : Easy installation, Durable, Resistant to high heat and corrosion

Style : Collar

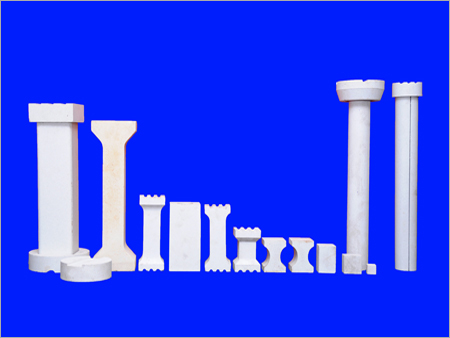

Kiln Pillars

Minimum Order Quantity : 100

Used For : Maintaining shelf separation and stacking in kilns

Load Capacity : High, depends on size and design (consult manufacturer)

Surface Treatment : Smooth/Glazed finish

Features : Dimensional stability, Thermal shock resistance, Lightweight

Style : Cylindrical/Columnar

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry