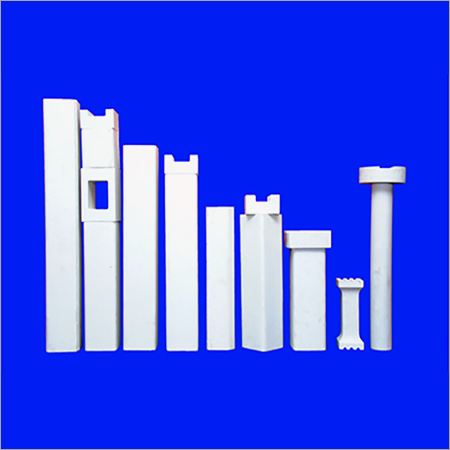

Kiln Furniture

Kiln Furniture Specification

- Power Source

- N/A (Not electrically powered)

- Used For

- Supporting wares during firing in high-temperature kilns

- Operating Temperature

- Up to 1700C

- Features

- Excellent durability, Long service life, Precise tolerances

- Load Capacity

- Tailored as per design requirement

- Automation Grade

- Manual

- Surface Treatment

- Smooth, Glazed, or as specified

- Material

- High Alumina Ceramic

- Style

- Rectangular / Custom shapes

- Properties

- High thermal stability, Corrosion resistant, Thermal shock resistance

- Capacity

- Varies as per design/application

- Power

- N/A (Passive component)

- Condition

- New

- Application

- Kilns, Furnaces, Heat treatment plants

Kiln Furniture Trade Information

- Minimum Order Quantity

- 100 Number

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Kiln Furniture

Kiln Furniture is necessary parts of ceramics. They are designed to provide stronger, reliable and efficient support to the kiln industry for making a range of products in refractories. With high sturdiness and durability, they ensure the development of quality assured pottery products. They are developed without any silica content from high quality ceramic, and other raw materials. Developed to withstand high temperatures up to 1750 deg C, they are sure to provide maximum performance and efficacy for years without any damage.

Features of Kiln Furniture:

- Excellent temperature resistant design

- Tight tolerances

- Flexible shape capabilities

- Good surface finish and thermally shock resistant

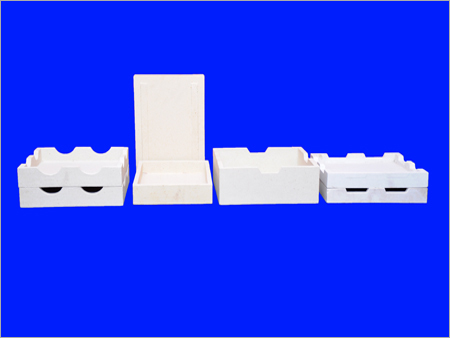

Tailored for Industrial Excellence

Our kiln furniture is designed for compatibility with various kiln types and applications, from ceramics production to industrial heat treatment. The materials high alumina content ensures consistent performance and durability, offering reliable support for ware during repeated high-temperature cycles. Customization is available for shape, size, and surface treatment, enabling precise solutions for diverse manufacturing needs.

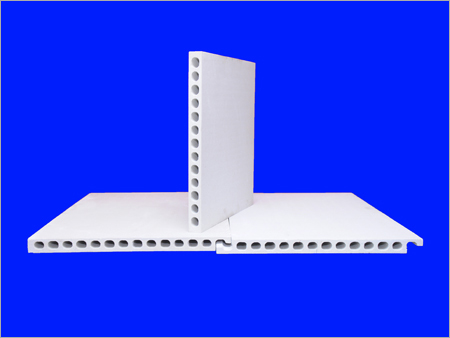

Unmatched Durability and Performance

With a flexural strength of over 45 MPa and low porosity, our kiln furniture withstands thermal shocks and resists chemical attack in harsh firing environments. The smooth or glazed surface finish enhances cleanliness and longevity, while tailored weight and load capacity accommodate specific operational demands. Each piece undergoes strict quality controls, delivering a product with a long service life and minimal maintenance requirements.

FAQs of Kiln Furniture:

Q: How do I choose the right size and shape of kiln furniture for my application?

A: Selecting the right kiln furniture involves considering the type of kiln, the dimensions of your wares, and thermal operating conditions. We offer both standard and custom sizes and shapes (round, rectangular, square, or specialized designs) to meet your unique production requirements. Our technical team can assist with recommendations based on your specific application.Q: What benefits do high alumina ceramic kiln furniture pieces offer?

A: High alumina ceramic provides excellent thermal stability, corrosion resistance, and outstanding resistance to thermal shock. This ensures reliable performance at temperatures up to 1700C, long service life, and precise dimensional tolerances, reducing operational costs and downtime.Q: When should kiln furniture be replaced or maintained?

A: Kiln furniture should be inspected regularly for signs of wear, such as cracking or warping, especially after repeated thermal cycling. Replace pieces if structural integrity is compromised. With proper handling and regular checks, our products offer extended service life due to their robust material properties.Q: Where are these kiln furniture products commonly used?

A: Our kiln furniture is utilized in kilns, furnaces, and heat treatment plantsmainly in ceramic manufacturing, metallurgy, and other industries requiring controlled high-temperature processes. They are suitable for all environments where supporting wares during firing is crucial.Q: What is the process for obtaining custom-designed kiln furniture?

A: To order custom kiln furniture, provide your desired dimensions, shapes, load requirements, and surface treatments. Our engineering team will review your specifications, offer design suggestions if needed, and manufacture pieces tailored to your requirements, ensuring optimum performance in your application.Q: How does the low porosity and water absorption benefit kiln furniture usage?

A: Low porosity and minimal water absorption (1.0%) decrease the risk of cracking from steam pressure during heating and enhance resistance to chemical attack. This translates into greater durability and fewer issues during firing, maintaining product consistency.Q: What packaging options are available and how is the product shipped?

A: Kiln furniture is securely packed in wooden boxes, cartons, or on pallets to protect against damage during transport. Packaging is selected based on the size and quantity of your order to ensure safe and reliable delivery to your location.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Extruded Batts Category

Roof Supporting System

Minimum Order Quantity : 100

Operating Temperature : 20C to 60C

Used For : Roof and Wall Support

Properties : Corrosion Resistant, High Strength

Material : Mild Steel, Hot Dip Galvanized Steel

Automation Grade : Manual

Refractory Collar

Minimum Order Quantity : 100

Operating Temperature : Up to 1700C

Used For : Sealing, jointing, and insulating hightemperature pipes and ducting

Properties : High thermal resistance, Abrasionresistant, Chemically inert

Material : HighGrade Refractory Ceramic

Automation Grade : Manual

Saggar Tray With Cover

Minimum Order Quantity : 100

Operating Temperature : Up to 1700C

Used For : Firing, Sintering, and Heat Treatment Processes

Properties : High Temperature Resistant, Thermal Shock Resistant

Material : High Alumina Ceramic

Automation Grade : Manual

Ceramic Saggar Tray

Minimum Order Quantity : 100

Operating Temperature : Up to 1600C

Used For : Supporting and Protecting Wares During Firing Process

Properties : High Thermal Stability, Chemically Inert

Material : High Alumina Ceramic

Automation Grade : Manual

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry