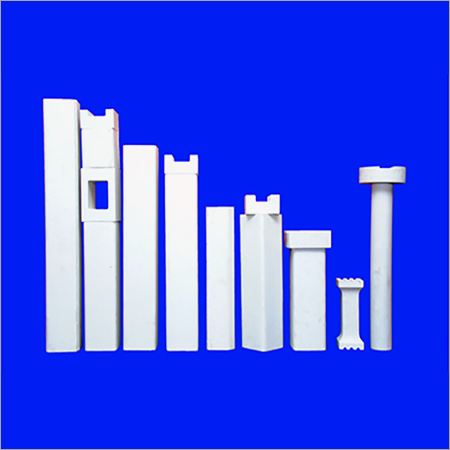

Refractory Collar

Refractory Collar Specification

- Load Capacity

- Varies as per size and installation

- Pressure Ratings

- Medium to high, based on application

- Used For

- Sealing, jointing, and insulating high-temperature pipes and ducting

- Surface Treatment

- Natural finish or as requested

- Features

- Easy installation, Durable, Resistant to high heat and corrosion

- Automation Grade

- Manual

- Operating Temperature

- Up to 1700C

- Material

- High-Grade Refractory Ceramic

- Style

- Collar

- Properties

- High thermal resistance, Abrasion-resistant, Chemically inert

- Capacity

- Custom sizes available

- Condition

- New

- Application

- Furnace lining, Kiln insulation, Industrial heat containment

- Color

- Off-white/Light yellow

- Thermal Expansion Coefficient

- Low

- Shock Resistance

- Excellent

- Product Code

- RC-HA-01

- Density

- 2.3-2.6 g/cm³

- Compressive Strength

- High (> 70 MPa)

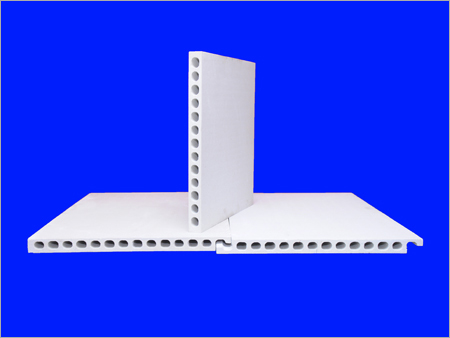

- Shape

- Round/Collar with central bore

- Porosity

- Low

Refractory Collar Trade Information

- Minimum Order Quantity

- 100 Number

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Refractory Collar

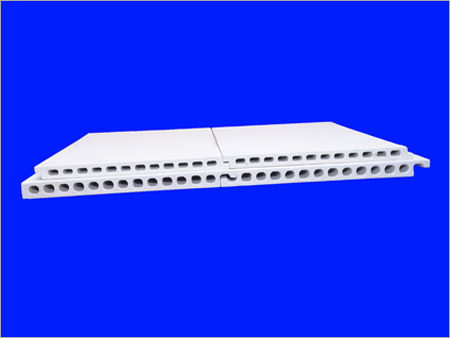

Round Tube Splicer And Collar are refractory products used in the kiln structure for ensuring to provide a better solution to kiln processes. They are developed from quality insulating bricks as well as ceramic fiber linings to make them ideal to withstand high temperatures and pressure. In addition, they are available in different sizes and dimensions to significantly increase the production rate as well as yields during the firing in kiln of ceramic products.

Features of Round Tube Splicer And Collar:

- Excellent thermal conductivity to help designing ceramic of high quality

- Easy to maintain and clean

- Save energy and reduce production cost

- Highly durable that can easily withstand high temperatures

Engineered for Extreme Environments

Our RC-HA-01 Refractory Collar is crafted for superior performance in high-temperature and high-pressure settings. The collars high-grade refractory ceramic resists intense heat, corrosion, and mechanical wear, making it indispensable for furnace lining and kiln insulation. Its robust and precise structure ensures secure sealing, jointing, and insulation for high-temperature pipes and equipment.

Versatile Applications & Installation

The collars design accommodates multiple industrial requirements, from heat containment in furnaces to insulating kilns, and sealing pipes operating under medium to high pressures. With custom sizes and manual installation capability, it is adaptable to new or existing setups. Its inherently low thermal expansion and porosity ensure long-term reliability and minimal maintenance.

FAQs of Refractory Collar:

Q: How is the RC-HA-01 Refractory Collar installed in industrial settings?

A: Installation is straightforward and can be performed manually, making it suitable for various piping and ducting configurations. It can be fitted seamlessly as part of furnace lining, kiln insulation, or in high-temperature pipe jointing, often without requiring specialized equipment.Q: What applications is this refractory collar best suited for?

A: The RC-HA-01 collar is ideal for furnace lining, kiln insulation, and industrial heat containment. It is commonly used for sealing, jointing, and thermally insulating pipes and ducting that operate under high temperatures and pressures.Q: When should I choose a high-density, low-porosity refractory collar?

A: Select a high-density, low-porosity collar when your application demands exceptional thermal resistance, minimal material degradation, and the capacity to endure mechanical and thermal stress, such as in high-performance furnaces and industrial kilns.Q: Where can the RC-HA-01 be used within a facility?

A: This refractory collar can be deployed wherever high-temperature sealing and insulation are critical, such as at pipe junctions, ductwork entry points, or component interfaces within furnaces and kilns.Q: What process is utilized in manufacturing these collars for high performance?

A: The collars are manufactured using advanced ceramic processing techniques to achieve a precise shape, high compressive strength, and consistent density. Customization is available to suit specific operational or dimensional requirements.Q: What benefits does the RC-HA-01 offer compared to conventional insulation products?

A: This collar provides superior shock resistance, low thermal expansion, high compressive strength, chemical inertness, and durability in extreme environments. It ensures long-term insulation efficiency and reliability, reducing downtime and maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Extruded Batts Category

Kiln Furniture

Minimum Order Quantity : 100

Used For : Supporting wares during firing in hightemperature kilns

Load Capacity : Tailored as per design requirement

Properties : High thermal stability, Corrosion resistant, Thermal shock resistance

Capacity : Varies as per design/application

Application : Kilns, Furnaces, Heat treatment plants

Saggar Trays

Minimum Order Quantity : 100

Used For : Holding Ceramics During Firing

Load Capacity : Depends on tray size, typically 125 kg

Properties : High Temperature Resistant, Nonreactive, Thermal Stability

Capacity : Custom sizes available (Standard: 1 kg to 25 kg) per tray

Application : Ceramic Firing, Powder Metallurgy, Furnace Processing

Ceramic Saggar Tray

Minimum Order Quantity : 100

Used For : Supporting and Protecting Wares During Firing Process

Load Capacity : Up to 15 kg

Properties : High Thermal Stability, Chemically Inert

Capacity : Customizable (commonly 215 kg payload)

Application : Ceramic Firing, Powder Sintering, Furnace Linings

Industrial Kiln Furniture

Minimum Order Quantity : 100 Pieces

Used For : Support and separation of products during firing

Load Capacity : Up to 2500 kg/m (varies with type and size)

Properties : High strength, thermal shock resistance, corrosion resistance

Capacity : Customizable as per requirement

Application : Used in kilns and furnaces for supporting ceramic ware

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry