Saggar Tray

Saggar Tray Specification

- Used For

- Firing and Sintering Ceramic Articles

- Load Capacity

- Supports Heavy Loads

- Surface Treatment

- Smooth Finish

- Operating Temperature

- Up to 1350C

- Pressure Ratings

- Atmospheric

- Features

- Long Life, Eco-Friendly, Reusable

- Automation Grade

- Manual

- Material

- High Quality Ceramic

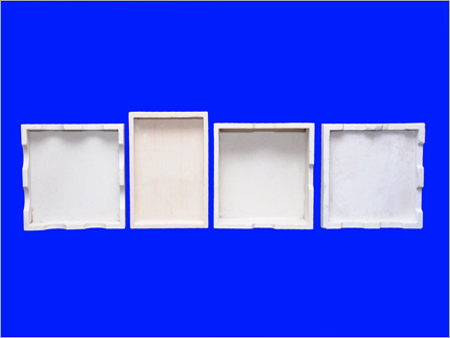

- Style

- Rectangular

- Properties

- Thermal Shock Resistant, High Refractory Strength

- Capacity

- Standard Capacity for Firing Ceramics

- Condition

- New

- Application

- Ceramic Industry, Kiln Firing

- Shelf Life

- Long, with proper handling

- Weight

- Varies according to size

- Shape

- Flat with raised edges

- Heat Retention

- Excellent

- Manufacturing Process

- Kiln-fired

- Maintenance

- Easy to clean, requires careful handling

- Color

- Off-white/Beige

- Stackability

- Yes

- Thickness

- Typically 10 mm to 30 mm

- Application Area

- Ceramics industry, pottery workshops, laboratories

Saggar Tray Trade Information

- Minimum Order Quantity

- 100 Number

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Saggar Tray

By a dedicated team of professionals, the provided Saggar Tray is designed and manufactured using top notch quality clay and cutting edge techniques under the observation of deft professionals. Highly cherished for its impeccable finish, sturdiness and optimum durability, this tray is used for serving water, tea, coffee etc. Available in various sizes, the offered Saggar Tray is highly admired among the clients.Engineered for High Performance

Saggar Trays are kiln-fired for increased refractory strength, enabling them to perform reliably at temperatures up to 1350C. Their sturdy construction and smooth finish make them ideal for repeated use in demanding environments found in ceramics industries and pottery workshops.

Versatile, Durable and Eco-Friendly

Designed with both durability and sustainability in mind, these trays are reusable and eco-friendly. Their standard capacity and stackability maximize efficiency, while the ceramic material resists thermal shock, reducing the risk of cracking or structural failure during intense firing cycles.

Easy Handling and Maintenance

Although Saggar Trays are robust and long-lasting, they require careful handling to maintain their smooth finish and structural integrity. Cleaning is simple, and proper storage ensures a prolonged shelf life, making them a cost-effective choice for various industrial and laboratory applications.

FAQs of Saggar Tray:

Q: How are Saggar Trays used in the ceramics industry?

A: Saggar Trays are primarily used to hold and protect ceramic articles during kiln firing and sintering processes. They help ensure even heat distribution and shield the pieces from direct flame, debris, or contamination, making them essential for producing high-quality ceramic items.Q: What is the process of manufacturing these trays?

A: These trays are manufactured by shaping high-quality ceramic materials into flat, rectangular forms with raised edges. They are then kiln-fired at high temperatures, which enhances their refractory strength and thermal shock resistance, making them durable for repeated high-temperature kiln firings.Q: When should I replace a Saggar Tray?

A: With proper handling and maintenance, Saggar Trays have a long shelf life and can withstand many firing cycles. However, they should be replaced if there are visible cracks, warping, or structural damage that might compromise their load-bearing capacity or thermal performance.Q: Where can Saggar Trays be used besides the ceramics industry?

A: Apart from the ceramics industry, Saggar Trays are commonly used in pottery workshops and laboratories where controlled, high-temperature processing of materials is required. Their excellent heat retention and durability make them suitable for various scientific and industrial settings.Q: What are the benefits of using high-quality ceramic Saggar Trays?

A: High-quality ceramic Saggar Trays offer superior thermal shock resistance, excellent heat retention, and the ability to support heavy loads. Their eco-friendly and reusable nature ensures lower long-term costs and less environmental impact, making them a sustainable choice for repeated industrial use.Q: How do I maintain and store Saggar Trays properly?

A: To maintain Saggar Trays, clean them gently after each use to prevent residue buildup and avoid thermal or physical shock during handling. Store them in a dry, stable environment, preferably stacked to save space while ensuring even weight distribution to prevent deformation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Extruded Batts Category

Kiln Furniture

Minimum Order Quantity : 100

Application : Kilns, Furnaces, Heat treatment plants

Capacity : Varies as per design/application

Properties : High thermal stability, Corrosion resistant, Thermal shock resistance

Surface Treatment : Smooth, Glazed, or as specified

Operating Temperature : Up to 1700C

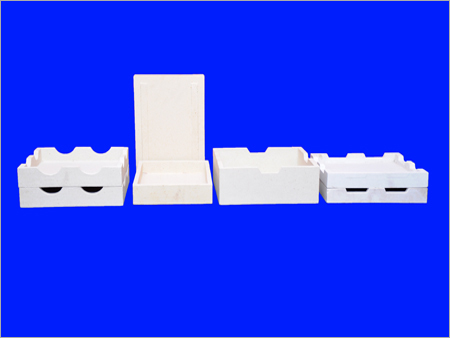

Saggar Tray With Cover

Minimum Order Quantity : 100

Application : Laboratory and Industrial Firing

Capacity : 2 kg (Approx.)

Properties : High Temperature Resistant, Thermal Shock Resistant

Surface Treatment : Smooth, Glazed Finish

Operating Temperature : Up to 1700C

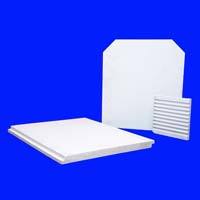

Industrial Kiln Furniture

Minimum Order Quantity : 100 Pieces

Application : Used in kilns and furnaces for supporting ceramic ware

Capacity : Customizable as per requirement

Properties : High strength, thermal shock resistance, corrosion resistance

Surface Treatment : Natural, Smooth Finish

Operating Temperature : Up to 1700C

Corner Cut Batts

Application : Wall, Roof and Duct Insulation, Building Construction

Capacity : Variable thickness and sizes available

Properties : Thermal Insulation, Fire Retardant, Acoustic Insulation

Surface Treatment : Nonwoven facing, Plain

Operating Temperature : Up to 230C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry