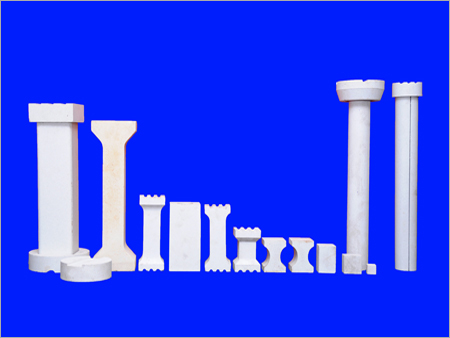

Kiln Pillars

Kiln Pillars Specification

- Operating Temperature

- Up to 1700C (varies with grade)

- Features

- Dimensional stability, Thermal shock resistance, Lightweight

- Used For

- Maintaining shelf separation and stacking in kilns

- Automation Grade

- Manual

- Surface Treatment

- Smooth/Glazed finish

- Load Capacity

- High, depends on size and design (consult manufacturer)

- Material

- Refractory Ceramic

- Style

- Cylindrical/Columnar

- Properties

- High-temperature resistance, Corrosion resistance, High strength

- Capacity

- Suitable for load-bearing applications in kiln furniture

- Condition

- New

- Application

- Support structure in kilns and furnaces

- Thermal Expansion

- Low

- Maximum Flexural Strength

- 120 MPa

- Diameter

- Available in 25 mm, 38 mm, 50 mm and custom sizes

- Length

- Ranges from 50 mm to 300 mm or as per requirement

- Porosity

- Low, <19%

- Chemical Resistance

- Excellent against alkalis and slags

- Density

- Approx. 2.7-3.0 g/cm

- Color

- Off White / Cream

- Compatibility

- Suitable for electric and gas kilns

- Shape

- Round/Cylindrical

Kiln Pillars Trade Information

- Minimum Order Quantity

- 100 Number

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Kiln Pillars

Exceptional Design & Material Quality

Crafted from high-quality refractory ceramic, our kiln pillars excel in strength, thermal resistance, and chemical durability. The round, columnar design and smooth finish enable stable stacking and dependable support for kiln furniture. Available in standard diameters or custom sizes, these pillars are engineered to maintain structural integrity even under high temperatures and heavy loads.

Optimized Performance for Kilns

Ideal for both electric and gas kilns, these pillars deliver reliable separation between shelves and facilitate efficient stacking of wares. Their low porosity ensures minimal absorption, while high flexural strength supports heavy applications. Operating seamlessly up to 1700C, they resist corrosion from alkalis and slags, making them indispensable for demanding kiln environments.

FAQs of Kiln Pillars:

Q: How are kiln pillars used within kilns and furnaces?

A: Kiln pillars are strategically placed between shelves or kiln furniture to provide sturdy support and maintain proper separation. This allows for efficient stacking of ceramic wares or materials during firing, ensuring evenly distributed heat and structural stability throughout the process.Q: What are the benefits of using off white or cream refractory ceramic kiln pillars?

A: These kiln pillars offer high-temperature resistance (up to 1700C), excellent chemical durability, low porosity, and strong load-bearing capacity. Their color and smooth finish help prevent contamination and make ware retrieval easier, while their lightweight design simplifies handling.Q: When should I consider custom-sized kiln pillars?

A: Custom-sized kiln pillars are recommended when standard diameters or lengths do not fit your specific kiln dimensions or stacking requirements. Manufacturers can tailor the size, length, or even properties to ensure optimal performance for unique kiln setups or specialty firing processes.Q: Where are these kiln pillars manufactured and supplied from?

A: These refractory ceramic kiln pillars are engineered, produced, and supplied by exporters and manufacturers based in India, with the capability to ship to international customers as well.Q: What makes these pillars suitable for heavy-duty applications?

A: With a flexural strength of at least 120 MPa, low thermal expansion, and a robust refractory ceramic composition, these pillars exhibit remarkable dimensional stability and load capacity, making them highly effective for heavy or repeated load-bearing scenarios within kilns.Q: How does the smooth or glazed finish enhance pillar performance?

A: The smooth or glazed surface minimizes friction during shelf placement and removal, helps prevent sticking or chemical interaction with wares, and reduces the risk of particulate contamination inside the kiln environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Extruded Batts Category

Roof Supporting System

Minimum Order Quantity : 100

Condition : New

Operating Temperature : 20C to 60C

Style : Modular, Customized

Material : Mild Steel, Hot Dip Galvanized Steel

Features : Easy Installation, Adjustable, High Load Bearing

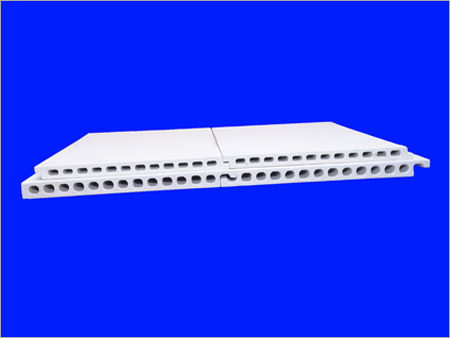

Kiln Furniture

Minimum Order Quantity : 100

Condition : New

Operating Temperature : Up to 1700C

Style : Rectangular / Custom shapes

Material : High Alumina Ceramic

Features : Excellent durability, Long service life, Precise tolerances

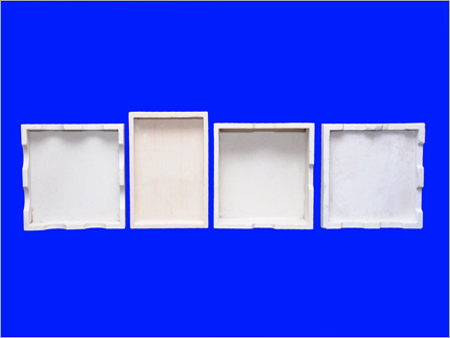

Saggar Tray

Minimum Order Quantity : 100

Condition : New

Operating Temperature : Up to 1350C

Style : Rectangular

Material : High Quality Ceramic

Features : Long Life, EcoFriendly, Reusable

Saggar Trays

Minimum Order Quantity : 100

Condition : New

Operating Temperature : Up to 1700C

Style : Rectangular Trays

Material : High Alumina Ceramics

Features : Thermal Shock Resistant, High Mechanical Strength, Corrosion Proof

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry