Industrial Kiln Furniture

Industrial Kiln Furniture Specification

- Load Capacity

- Up to 2500 kg/m (varies with type and size)

- Surface Treatment

- Natural, Smooth Finish

- Used For

- Support and separation of products during firing

- Operating Temperature

- Up to 1700C

- Automation Grade

- Manual

- Features

- Long service life, low thermal mass, easy installation

- Material

- High Alumina Ceramic

- Style

- Rectangular & Circular Shapes

- Properties

- High strength, thermal shock resistance, corrosion resistance

- Capacity

- Customizable as per requirement

- Condition

- New

- Application

- Used in kilns and furnaces for supporting ceramic ware

- Max Bending Strength

- 60 MPa

- Thermal Expansion Coefficient

- <8 x 10/C

- Thickness

- 10 mm to 60 mm

- Color

- Off-White, Beige

- Resists

- Creep, deformation at high temperatures

- Water Absorption

- 5%

- Density

- 2.7-2.8 g/cm

- Shape Options

- Plate, Setter, Beam, Bat, Saggar

- Manufacturing Tolerance

- 1 mm

- Porosity

- <18%

Industrial Kiln Furniture Trade Information

- Minimum Order Quantity

- 100 Pieces

- FOB Port

- As per location

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Industrial Kiln Furniture

The offered Kiln Furniture is manufactured and designed under the observation of adroit professionals using pristine quality clay and state of the art techniques. This furniture is highly admired to be used at homes, hotels, resorts and similar other places for accommodating varied items like kitchenware, books etc. Known for its excellent durability, long lasting sheen and fine finish, this Kiln Furniture can be bought from us at rock bottom rates.

Precision-Crafted for Demanding Kiln Environments

Manufactured with strict tolerance (1 mm) and high-density (2.72.8 g/cm) high alumina ceramic, our kiln furniture supports heavy loads and endures intense thermal cycling. Its smooth, natural finish and low water absorption (5%) make it suitable for the most rigorous industrial settings.

Versatile Support Solutions for Ceramics Processing

Offered in diverse shapesplates, setters, beams, bats, and saggarswith customizable sizes and thicknesses, our kiln furniture is ideal for supporting and separating a wide range of ceramic products during firing. Its high resistance to creep and deformation ensures dimensional stability in high-temperature applications.

Exceptional Durability and Installation Ease

With proven corrosion resistance and minimal thermal mass, our products promise a long service life and simplified manual installation. The low porosity design further enhances thermal insulation and reduces energy consumption in both new and retrofit kilns.

FAQs of Industrial Kiln Furniture:

Q: How does high alumina ceramic kiln furniture benefit high-temperature firing processes?

A: High alumina ceramic provides superior thermal shock resistance, high strength, and excellent resistance to creep and deformation at elevated temperatures (up to 1700C). This ensures reliable support and separation of ceramic ware, minimizing product defects during firing.Q: What are the available shape and thickness options for this kiln furniture?

A: We offer kiln furniture in plates, setters, beams, bats, and saggars, in both rectangular and circular shapes. Thickness can be customized from 10 mm to 60 mm according to your specific kiln or furnace requirements.Q: When should I choose high alumina kiln furniture over other materials?

A: High alumina kiln furniture is ideal when your process demands high load capacity, resistance to thermal stress, minimal deformation, and durability at temperatures up to 1700C. It is particularly suited for industries where precise firing and product quality are crucial.Q: Where is this kiln furniture typically used?

A: Our kiln furniture is widely used in industrial kilns and furnaces across ceramics manufacturing sectors for supporting and separating ceramic ware, tiles, and refractory products throughout the firing and sintering processes.Q: What is the typical manufacturing process for these kiln furniture products?

A: The process involves shaping high alumina ceramic into specified forms, followed by high-temperature firing to achieve the required strength, density, and surface finish. Each piece is precisely machined to meet a 1 mm tolerance and undergoes quality checks for density, porosity, and performance.Q: How do I select the correct kiln furniture for my application?

A: Consider your kiln/furnace dimensions, product type, required load capacity (up to 2500 kg/m), operating temperature, and preferred shapes or thickness. Our team can assist in customizing the size and capacity based on your requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Extruded Batts Category

Roof Supporting System

Minimum Order Quantity : 100

Style : Modular, Customized

Features : Easy Installation, Adjustable, High Load Bearing

Condition : New

Application : Mining, Tunnels, Underground Construction

Capacity : Up to 30 Tons

Kiln Furniture

Minimum Order Quantity : 100

Style : Rectangular / Custom shapes

Features : Excellent durability, Long service life, Precise tolerances

Condition : New

Application : Kilns, Furnaces, Heat treatment plants

Capacity : Varies as per design/application

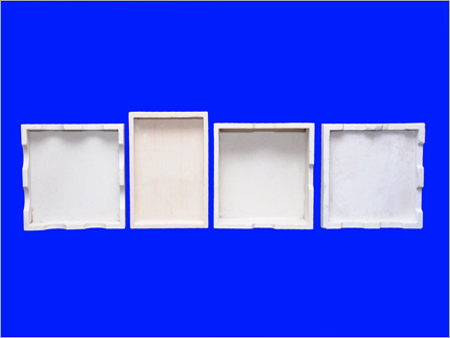

Saggar Tray

Minimum Order Quantity : 100

Style : Rectangular

Features : Long Life, EcoFriendly, Reusable

Condition : New

Application : Ceramic Industry, Kiln Firing

Capacity : Standard Capacity for Firing Ceramics

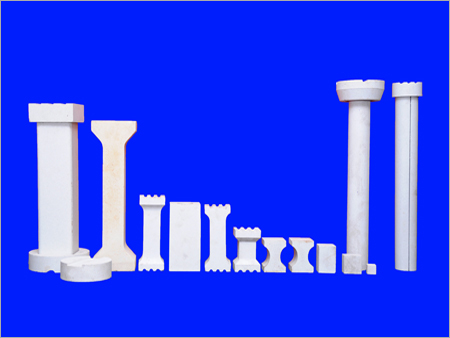

Kiln Pillars

Minimum Order Quantity : 100

Style : Cylindrical/Columnar

Features : Dimensional stability, Thermal shock resistance, Lightweight

Condition : New

Application : Support structure in kilns and furnaces

Capacity : Suitable for loadbearing applications in kiln furniture

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry