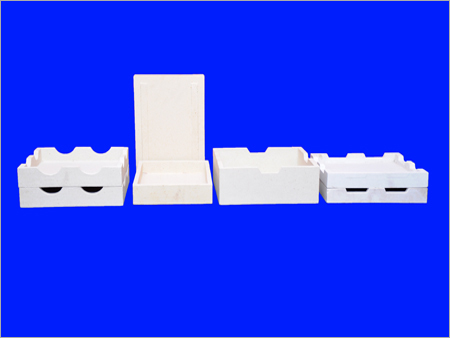

Ceramic Saggar Tray

Ceramic Saggar Tray Specification

- Features

- Refractory, Durable, Thermal Shock Resistant, High Mechanical Strength

- Operating Temperature

- Up to 1600C

- Load Capacity

- Up to 15 kg

- Automation Grade

- Manual

- Surface Treatment

- Glazed or Unglazed Surface

- Used For

- Supporting and Protecting Wares During Firing Process

- Material

- High Alumina Ceramic

- Style

- Rectangular

- Properties

- High Thermal Stability, Chemically Inert

- Capacity

- Customizable (commonly 2-15 kg payload)

- Condition

- New

- Application

- Ceramic Firing, Powder Sintering, Furnace Linings

Ceramic Saggar Tray Trade Information

- Minimum Order Quantity

- 100 Number

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Ceramic Saggar Tray

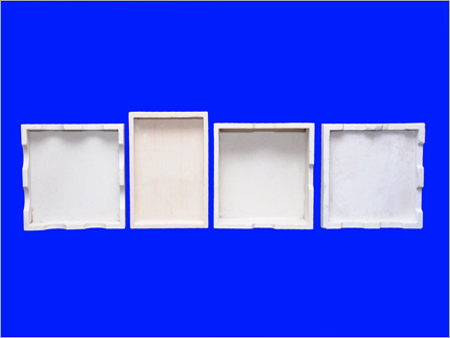

Ceramic Saggar Tray is designed from high quality and pure ceramic to add maximum durability. This is available in box shaped widely used in the firing of pottery for protecting ware from any fired inside a kiln. It provides absolute protection to the ware from gases, flame, smoke, and kiln debris. It is designed from cordierite ceramic, alumina ceramic, mullite ceramic silicon carbide, etc. It can be thermally cycled for hundreds of times without any deformation and degradation.

Features of Ceramic Saggar Tray:

- Ideal for high purity mullite & alumina refractories

- High temperature resistant design with good strength

- Tight tolerances with flexible shape capabilities

- Excellent surface finishing with thermally shock resistant design

Optimal Protection for Industrial Firing

Engineered for durability, our high alumina Ceramic Saggar Trays shield wares from direct flame and contaminants during high-temperature firing. The raised rim design ensures items stay secure, minimizing risk and enhancing efficiency over multiple firing cycles.

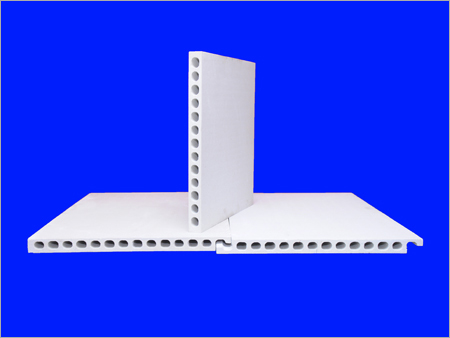

Built to Withstand Extreme Conditions

With thermal stability up to 1600C and resistance to chemical corrosion, these saggars are ideal for rigorous industrial applications. Their chemically inert surfaces, whether glazed or unglazed, guarantee long-lasting use even in the most challenging kiln and furnace environments.

Customizable for Your Industrial Needs

Our saggar trays are available in various dimensions, capacities, and surface finishes, tailored to your operational requirements. From small-scale ceramics to high-volume powder sintering, customization ensures the perfect fit for your manufacturing processes.

FAQs of Ceramic Saggar Tray:

Q: How are Ceramic Saggar Trays used during the firing process?

A: They support and protect ceramic wares or materials during firing by providing a safe, thermally stable enclosure that prevents direct exposure to flame, gases, or impurities within industrial kilns or furnaces.Q: What are the key benefits of using high alumina Ceramic Saggar Trays?

A: These trays deliver superior thermal shock resistance, high mechanical strength, and chemical inertness, resulting in longer lifespan and the ability to endure multiple firing cycles at temperatures up to 1600C.Q: When should I choose glazed versus unglazed saggars?

A: Glazed surfaces reduce adhesion of materials and make cleaning easier, while unglazed trays offer better gas permeability, preferred in certain firing processes. The choice depends on specific application needs and processing requirements.Q: Where are these Ceramic Saggar Trays typically used?

A: Commonly employed in industrial environments such as ceramic firing facilities, powder sintering plants, and in furnace linings, particularly where high temperature and chemical exposure is routine.Q: What is the process for customizing saggar trays?

A: Customization is available based on capacity, dimensions, and surface treatment. Provide your specifications regarding tray size, payload, and operating conditions to ensure optimal integration with your equipment.Q: How do these trays handle thermal shock and chemical corrosion?

A: Manufactured from high alumina ceramic, they exhibit exceptional resilience to rapid temperature changes and corrosive atmospheres, extending their usability across tough industrial cycles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Extruded Batts Category

Roof Supporting System

Minimum Order Quantity : 100

Capacity : Up to 30 Tons

Condition : New

Operating Temperature : 20C to 60C

Features : Easy Installation, Adjustable, High Load Bearing

Properties : Corrosion Resistant, High Strength

Kiln Furniture

Minimum Order Quantity : 100

Capacity : Varies as per design/application

Condition : New

Operating Temperature : Up to 1700C

Features : Excellent durability, Long service life, Precise tolerances

Properties : High thermal stability, Corrosion resistant, Thermal shock resistance

Saggar Tray With Cover

Minimum Order Quantity : 100

Capacity : 2 kg (Approx.)

Condition : New

Operating Temperature : Up to 1700C

Features : Reusable, Durable, Thermal Stability, Corrosion Resistance

Properties : High Temperature Resistant, Thermal Shock Resistant

Saggar Tray

Minimum Order Quantity : 100

Capacity : Standard Capacity for Firing Ceramics

Condition : New

Operating Temperature : Up to 1350C

Features : Long Life, EcoFriendly, Reusable

Properties : Thermal Shock Resistant, High Refractory Strength

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry