Saggar Trays

Saggar Trays Specification

- Features

- Thermal Shock Resistant, High Mechanical Strength, Corrosion Proof

- Operating Temperature

- Up to 1700C

- Load Capacity

- Depends on tray size, typically 1-25 kg

- Used For

- Holding Ceramics During Firing

- Surface Treatment

- Glazed / Unglazed

- Automation Grade

- Manual

- Material

- High Alumina Ceramics

- Style

- Rectangular Trays

- Properties

- High Temperature Resistant, Non-reactive, Thermal Stability

- Capacity

- Custom sizes available (Standard: 1 kg to 25 kg) per tray

- Condition

- New

- Application

- Ceramic Firing, Powder Metallurgy, Furnace Processing

- Manufacturing Process

- Kiln-fired ceramic

- Moisture Absorption

- Low

- Color

- Natural Off-white

- Usage

- Industrial, laboratory, pottery

- Heat Resistance

- Excellent

- Weight

- Varies as per size

- Thickness

- 15-30 mm

- Shape

- Flat with raised edges

- Dimensions

- Can be customized

Saggar Trays Trade Information

- Minimum Order Quantity

- 100 Number

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Saggar Trays

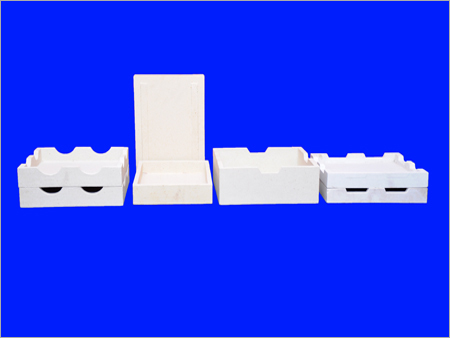

Open Saggar Tray is kiln furniture designed in the form of a ceramic boxlike container widely used in the firing of pottery. It is used to enclose or protect the ware from high temperatures inside a kiln. It is also used to protect ware from open flame, gases, kiln debris, etc. It is designed from high quality alumina ceramic, mullite ceramic silicon carbide, cordierite ceramic and other materials to ensure to provide maximum strength as well as durability.

Features of Open Saggar Tray:

- Large in size for providing complete protection to products during firing

- Widely used in the domain of glost or biscuit firing of tableware

- Developed from semi-dry pressing and casting

- Available with good thermal shock resistant design

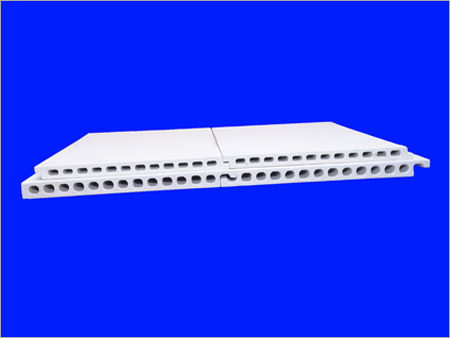

Durable High Alumina Construction

Crafted using high alumina ceramics, these Saggar Trays deliver outstanding strength, thermal shock resistance, and minimal moisture absorption. Their construction method and material selection ensure stability and resistance to corrosion, making them ideal for demanding thermal applications.

Versatile Industrial Applications

Engineered for use in ceramic firing, powder metallurgy, and other furnace processes, these trays offer flexible utility. Their flat shape with raised edges securely holds materials during high-temperature procedures, safeguarding your valuable components.

Customizable Dimensions and Capacity

Available in a variety of sizes and load capacities, these trays can be tailored to specific requirements, accommodating up to 25 kg per tray. Both glazed and unglazed surface treatments are offered to match particular application needs.

FAQs of Saggar Trays:

Q: How are Saggar Trays manufactured?

A: Saggar Trays are produced using a kiln-fired process with high alumina ceramics, ensuring durability, high temperature resistance, and excellent mechanical strength.Q: What makes these trays suitable for high-temperature processes?

A: The trays high alumina ceramic composition provides exceptional thermal stability and heat resistance, allowing them to withstand temperatures up to 1700C, making them ideal for demanding furnace and firing operations.Q: When should I use glazed versus unglazed Saggar Trays?

A: Glazed trays are best suited for processes requiring a smoother, non-porous surface, while unglazed trays offer increased permeability, which may be preferred in some firing or processing environments depending on material requirements.Q: Where are these trays commonly used?

A: These trays are widely used in ceramic kilns, laboratories, industrial furnaces, and powder metallurgy operations throughout industries that require reliable, high-temperature materials handling.Q: Can the dimensions and load capacity be customized?

A: Yes, Saggar Trays come in customizable dimensions and capacities, ranging from 1 kg up to 25 kg per tray, allowing them to meet specific equipment and process requirements.Q: What are the key benefits of using high alumina ceramic trays?

A: High alumina ceramic trays offer excellent thermal shock resistance, low moisture absorption, non-reactivity with processes substances, and strong mechanical integrity, ensuring long service life in industrial applications.Q: How do Saggar Trays improve the firing or furnace process?

A: Saggar Trays provide thermal protection and support for ceramics and other materials, enabling consistent heating, preventing contamination, and reducing product loss during high-temperature treatments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Extruded Batts Category

Roof Supporting System

Minimum Order Quantity : 100

Style : Modular, Customized

Operating Temperature : 20C to 60C

Features : Easy Installation, Adjustable, High Load Bearing

Condition : New

Material : Mild Steel, Hot Dip Galvanized Steel

Kiln Furniture

Minimum Order Quantity : 100

Style : Rectangular / Custom shapes

Operating Temperature : Up to 1700C

Features : Excellent durability, Long service life, Precise tolerances

Condition : New

Material : High Alumina Ceramic

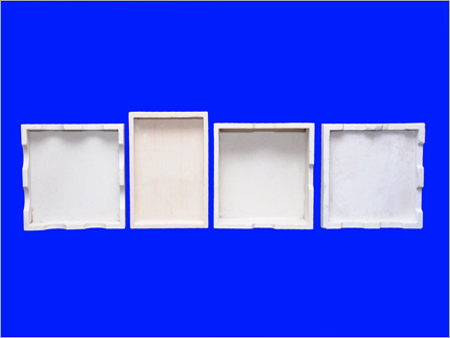

Saggar Tray With Cover

Minimum Order Quantity : 100

Style : Rectangular with Lid

Operating Temperature : Up to 1700C

Features : Reusable, Durable, Thermal Stability, Corrosion Resistance

Condition : New

Material : High Alumina Ceramic

Saggar Tray

Minimum Order Quantity : 100

Style : Rectangular

Operating Temperature : Up to 1350C

Features : Long Life, EcoFriendly, Reusable

Condition : New

Material : High Quality Ceramic

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry