Ceramic Extruded Batts

Ceramic Extruded Batts Specification

- Operating Temperature

- Up to 1400C

- Surface Treatment

- Smooth, slip-resistant finish

- Automation Grade

- Manual

- Used For

- Supporting ceramic ware during firing processes

- Load Capacity

- High; designed to withstand heavy weights

- Features

- High durability, dimensional accuracy, corrosion resistance, long service life

- Material

- Ceramic

- Style

- Extruded

- Properties

- High thermal stability, Excellent mechanical strength, Good resistance to thermal shock

- Capacity

- Suitable for heavy load bearing in kiln applications

- Condition

- New

- Application

- Used in industrial kilns, furnaces, and ceramic processing plants

- Water Absorption

- <0.5%

- Shape

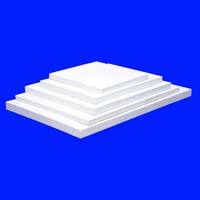

- Rectangular, Custom shapes available

- Thickness

- Available in multiple thicknesses (typically 12 mm to 50 mm)

- Color

- Light beige to pale yellow

- Manufacturing Process

- Extrusion

- Porosity

- Low porosity

- MOQ

- As per customer requirement

- Packaging Type

- Wooden Crate/Box, as per customer requirement

- Flexural Strength

- 35 to 50 MPa

- Density

- Approx. 2.3-2.5 g/cm³

Ceramic Extruded Batts Trade Information

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Ceramic Extruded Batts

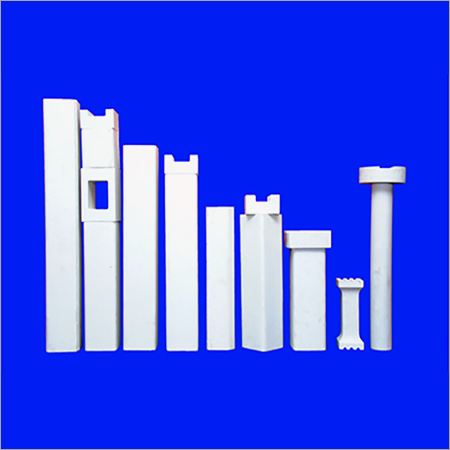

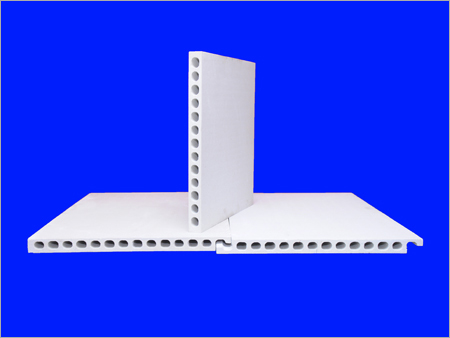

Pressed Batts :-

Ceramic Extruded Batts or Pressed Batts are designed in strong and sturdy yet lightweight design to ensure to provide the best results. They are available in a range of different dimensions from 18mm 25mm to 38mm thinness. They are available with a part-hollow section that ensures to save energy while heating the batts during the firing in kiln. In addition, they are also available with more perforation to permit extra heat flow. Designed from high-quality NSIC (nitride bond), RBSIC (reaction bond), cordierite, alumina and other materials, they provide long lasting performance.

Features of Ceramic Extruded Batts or Pressed Batts:

- Minimum density with maximum durability

- Can withstand maximum temperature during firing

- Save energy in every firing

- Resistant to thermal shock cracking

Optimized for Heavy Load Kiln Applications

Ceramic Extruded Batts are designed to withstand the rigorous demands of industrial kilns, making them ideal for ultra-heavy load bearing. Their exceptional mechanical strength and low water absorption ensure they maintain structural integrity under repeated thermal cycles, while their high thermal stability supports reliable, long-term performance in high-temperature environments.

Customizable to Fit Unique Requirements

Available in standard rectangular shapes as well as custom dimensions, these batts cater to a broad range of applications. Multiple thickness options from 12 mm to 50 mm provide flexibility for varying kiln setups, ensuring that both small-scale and industrial ceramic producers find a compatible solution. Each batt is manufactured according to specific customer requirements, ensuring optimal fit and function.

Engineered for Durability and Precision

The extrusion manufacturing process yields products with consistent density (2.3-2.5 g/cm) and low porosity, resulting in a smooth, slip-resistant surface. These attributes contribute to their long lifespan, high dimensional accuracy, and excellent resistance to thermal shock and corrosion, making Ceramic Extruded Batts a preferred choice for demanding firing operations.

FAQs of Ceramic Extruded Batts:

Q: What are Ceramic Extruded Batts used for in industrial settings?

A: Ceramic Extruded Batts are primarily used to support ceramic ware during firing processes in industrial kilns, furnaces, and ceramic processing plants. Their high strength and stability allow them to bear heavy loads even at extreme temperatures, ensuring safe and efficient firing.Q: How are these ceramic batts manufactured and finished?

A: These batts are produced through an extrusion process, which provides a smooth, slip-resistant finish and ensures uniform density and low porosity across all products. The result is a highly durable and precise kiln shelf suitable for industrial applications.Q: What thickness and shapes are available for Ceramic Extruded Batts?

A: The batts come in multiple thicknesses ranging from 12 mm to 50 mm to suit different kiln requirements. While the standard shape is rectangular, custom shapes and sizes can be supplied based on customer specifications, offering versatility for various kiln designs.Q: What is the maximum operating temperature and load capacity of these batts?

A: Ceramic Extruded Batts can operate at temperatures up to 1400C and are engineered to support heavy weights, making them suitable for use in high-capacity, high-temperature kilns.Q: What are the benefits of using ceramic extruded batts over other kiln support solutions?

A: These batts offer high thermal stability, excellent mechanical strength, resistance to thermal shock and corrosion, as well as a long service life. Their dimensional accuracy and low water absorption further enhance operational safety and consistency during firing processes.Q: How are Ceramic Extruded Batts packaged and supplied?

A: They are securely packaged in wooden crates or boxes as per the customers requirement, ensuring safe transportation and delivery. Minimum order quantity (MOQ) and packaging specifications are flexible and can be tailored to individual needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Extruded Batts Category

Kiln Furniture

Minimum Order Quantity : 100

Properties : High thermal stability, Corrosion resistant, Thermal shock resistance

Automation Grade : Manual

Surface Treatment : Smooth, Glazed, or as specified

Style : Rectangular / Custom shapes

Operating Temperature : Up to 1700C

Refractory Collar

Minimum Order Quantity : 100

Properties : High thermal resistance, Abrasionresistant, Chemically inert

Automation Grade : Manual

Surface Treatment : Natural finish or as requested

Style : Collar

Operating Temperature : Up to 1700C

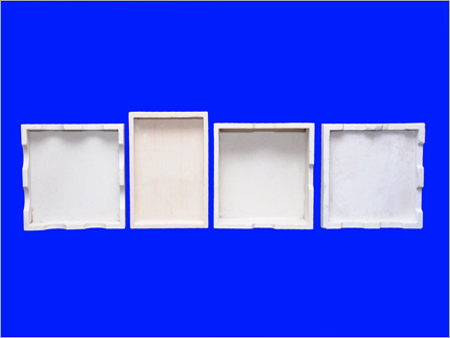

Saggar Tray

Minimum Order Quantity : 100

Properties : Thermal Shock Resistant, High Refractory Strength

Automation Grade : Manual

Surface Treatment : Smooth Finish

Style : Rectangular

Operating Temperature : Up to 1350C

Ceramic Saggar Tray

Minimum Order Quantity : 100

Properties : High Thermal Stability, Chemically Inert

Automation Grade : Manual

Surface Treatment : Glazed or Unglazed Surface

Style : Rectangular

Operating Temperature : Up to 1600C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry