Pressed Batts

Pressed Batts Specification

- Automation Grade

- Manual installation

- Features

- Light weight, easy to install, water repellent, non-combustible, eco-friendly

- Used For

- Used for insulation in walls, roofs, and industrial enclosures

- Load Capacity

- Varies as per density and thickness

- Surface Treatment

- Plain, non-combustible surface

- Operating Temperature

- Up to 250C

- Material

- Resin Bonded Glass Wool

- Style

- Pressed Batts

- Properties

- Excellent thermal insulation, sound absorption, fire resistance

- Capacity

- Custom sizes available

- Condition

- New

- Application

- Thermal and acoustic insulation in buildings, HVAC, industrial plants

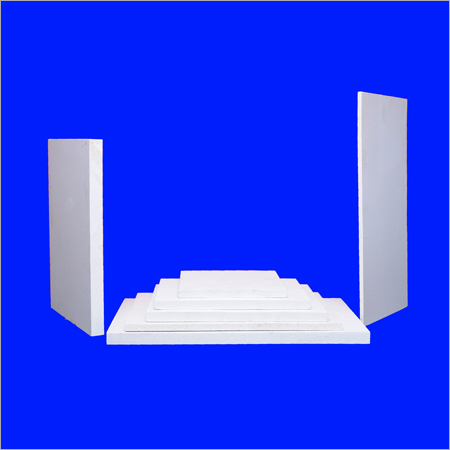

- Width

- 400 mm to 600 mm

- Water Absorption

- <1% by Volume

- Density

- 16 to 48 kg/m³

- Packing

- Polythene Bags / Cartons

- Odor

- Odorless

- Thickness

- 25 mm to 100 mm

- Length

- 600 mm to 1200 mm

- Fire Class

- Class 1 (BS 476 Part 7) / Class O (BS 476 Part 6)

- Color

- Golden Yellow

Pressed Batts Trade Information

- Minimum Order Quantity

- 100 Number

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Pressed Batts

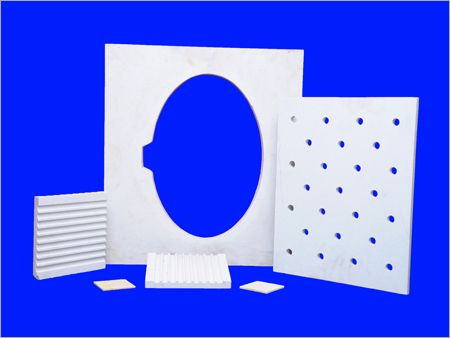

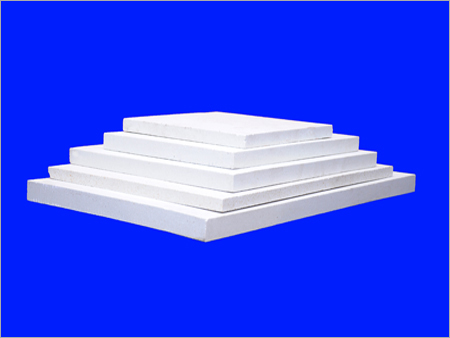

Pressed Batts are known as refractory tiles or slabs that are widely used as components of the kiln car superstructure. They are also designed to support ware during the furnace firing cycle. These Different Size Pressed Batts are available in sizes from 1000mm x 1000mm, 1800mm x 840mm, etc. In addition, they can be availed in square, rectangular, and other shapes as per the demands. They are the excellent solution to insulation without changing the core structure.

Features of Different Size Pressed Batts:

- Excellent dimensional stability

- High flexural strength under normal temperature

- Outstanding thermal shock resistant design

- Available in a variety of geometries from hollowed, solid to flat or ribbed

Outstanding Thermal and Acoustic Insulation

Pressed Batts are engineered with resin bonded glass wool to ensure exceptional thermal insulation, helping to control indoor temperatures and reduce energy bills. Additionally, their superior sound absorption properties make them perfect for applications requiring noise reduction, such as office partitions, recording studios, and industrial spaces.

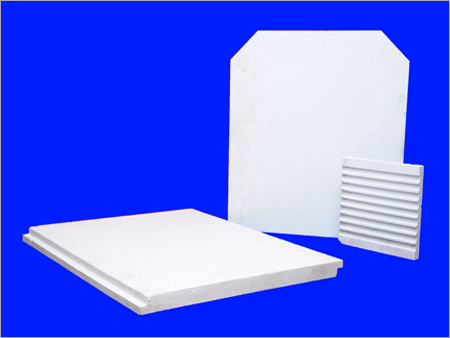

Fire Resistance and Safety Compliance

Designed for enhanced fire safety, these batts meet Class 1 (BS 476 Part 7) and Class O (BS 476 Part 6) fire resistance standards. Their non-combustible surface adds an extra layer of security, making them suitable for use in both residential and industrial environments, where fire safety is paramount.

Simple Installation and Eco-Friendly Composition

Lightweight Pressed Batts are easy to handle and install manually, without the need for special tools or training. These batts are eco-friendly, water repellent, and odorless, making them a sustainable and safe option for insulating a wide variety of structures. Custom sizing is available to meet specific project requirements.

FAQs of Pressed Batts:

Q: How are Pressed Batts installed in buildings and industrial enclosures?

A: Pressed Batts are designed for manual installation, fitting easily within wall cavities, roof structures, or industrial enclosures. Simply place the batts between framing members or mounting brackets, ensuring a snug fit to minimize thermal bridging and air gaps.Q: What are the primary benefits of using Pressed Batts for insulation?

A: Pressed Batts provide excellent thermal insulation, superior sound absorption, and outstanding fire resistance. They are lightweight, easy to install, resistant to water absorption, and eco-friendly, making them suitable for a wide range of applications.Q: When should I use Pressed Batts in my project?

A: Pressed Batts are ideal during building construction or renovation when thermal or acoustic insulation is required in walls, roofs, HVAC ducts, or industrial enclosures. Their fire-resistant properties also make them beneficial wherever safety regulations apply.Q: Where can Pressed Batts be used within different types of facilities?

A: These batts are versatile and well-suited for use in commercial, residential, and industrial facilities. Common applications include insulation for walls, roofs, HVAC systems, and machinery enclosures requiring both thermal and acoustic control.Q: What is the manufacturing process of Pressed Batts?

A: Pressed Batts are manufactured using resin bonded glass wool, which is processed under controlled conditions to achieve the desired density and thickness. The batts are then cut to size and packed in polythene bags or cartons for delivery.Q: How does the water repellent feature enhance product performance?

A: With water absorption less than 1% by volume, Pressed Batts maintain their insulating and acoustic properties even in humid conditions, reducing the risk of mold growth and structural degradation.Q: Are custom sizes available for unique insulation projects?

A: Yes, Pressed Batts can be supplied in custom sizes to fit specific project requirements, ensuring optimal coverage and insulation performance for any building or industrial setup.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plain Batts Category

Ceramic Batts

Minimum Order Quantity : 100

Capacity : Customizable

Surface Treatment : Natural finish

Automation Grade : Manual

Application : Kiln furniture, ceramic industry

Operating Temperature : Up to 1500C

Cordierite Batts

Minimum Order Quantity : 100

Capacity : Varies as per size (Custom Sizes Available)

Surface Treatment : Uncoated / Natural finish

Automation Grade : Manual/Nonautomated

Application : Used in kiln furniture, pottery, ceramic firing, and heat treatment

Operating Temperature : Up to 1320C

Refractory Batts

Minimum Order Quantity : 100

Capacity : Custom sizes available

Surface Treatment : Uncoated / plain ceramic finish

Automation Grade : Manual

Application : Kiln furniture, kiln shelves, furnace lining

Operating Temperature : Up to 1500C

Saggar Tray With Cover

Capacity : Medium to Large (customizable)

Surface Treatment : Smooth Unglazed Finish

Automation Grade : Manual

Application : Industrial Firing, Lab Applications

Operating Temperature : Up to 1350C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry