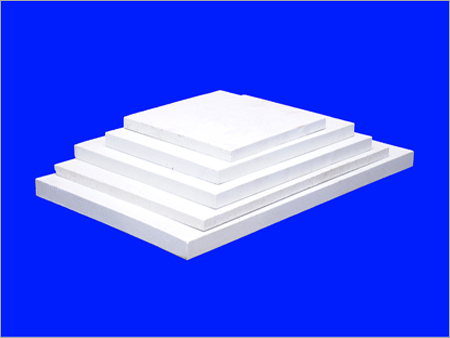

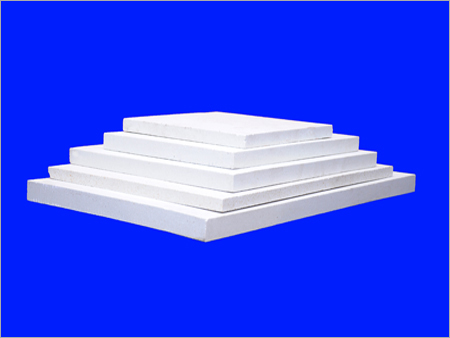

Extruded Batts

Extruded Batts Specification

- Load Capacity

- Depends on dimensions, consult manufacturer

- Used For

- Thermal insulation in high temperature processes

- Surface Treatment

- Smooth finish

- Automation Grade

- Manual

- Features

- Lightweight, Durable, Chemically stable, Easy to install

- Operating Temperature

- Up to 1450C

- Material

- Ceramic Fibre

- Style

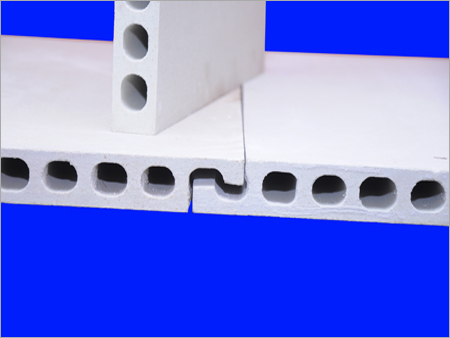

- Extruded Batts

- Properties

- High temperature resistance, thermal shock stability, low thermal conductivity

- Capacity

- Custom sizes available

- Condition

- New

- Application

- Industrial furnaces, Kilns, Lining for heat treatment plants

- Water Absorption

- Low

- Width

- 150 mm to 650 mm (customizable)

- Density

- 1.2-1.5 g/cm³

- Thermal Conductivity

- 0.11-0.15 W/mK at 1000°C

- Toxicity

- Non-toxic

- Thickness

- 10 mm to 50 mm

- Length

- 300 mm to 1200 mm (customizable)

- Packaging Type

- Crate or pallet packing

- Compressive Strength

- High

- Colour

- Light grey

- Shape

- Flat rectangular batts

- Refractoriness

- 1100°C continuous service

Extruded Batts Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Extruded Batts

Extruded Batts are designed using vacuum extruding technology to provide better support and performance to the new generation refractory kiln. They are designed with excellent loading capability along with excellent creep resistant design at high temperature. With long service life and energy saving, it provides the best performance for sanitary ware as well as glass-ceramic sintering. They are available with sturdy and highly durable design to provide maximum strength.

Features of Extruded Batts:

- Weight reduction of 35% - 50% and enhanced load capacity

- Reduces fuel consumption up to 70%

- No damage and bend at high temperatures

- Disperses heat and tolerate extremes of hot and cold temperature

Engineered for High-Temperature Performance

Our extruded batts deliver stability and robust performance in high-temperature processes. Built from premium ceramic fibre, these batts are designed to withstand thermal shocks, making them ideal for kiln linings or furnace insulation. The batts smooth surface ensures efficient handling and installation, while their chemical stability contributes to a longer product lifespan even in tough conditions.

Versatile Customization for Your Needs

With lengths ranging from 300 mm to 1200 mm and widths from 150 mm to 650 mm, our flat rectangular batts can be tailored to fit a variety of industrial applications. Thicknesses between 10 mm and 50 mm further enhance adaptability, addressing specific insulation requirements for diverse projects in the manufacturing, metallurgical, and heat treatment industries.

FAQs of Extruded Batts:

Q: How are the extruded ceramic fibre batts installed in industrial furnaces or kilns?

A: These batts are manually installed by placing them directly onto furnace walls or lining structures. Their lightweight and smooth finish make handling and fitting straightforward. Installation guidelines may vary based on individual project needs; consulting the manufacturer for best practices is recommended.Q: What applications are most suitable for these ceramic fibre batts?

A: The batts are ideal for use in industrial furnaces, kiln linings, and heat treatment plant insulation. They are specifically engineered for environments requiring excellent thermal resistance, stability at high temperatures, and low thermal conductivity.Q: When should I consider using custom-sized batts for my process?

A: Custom sizes should be selected when standard dimensions do not adequately cover the insulation area, or when specific thicknesses are needed for enhanced thermal protection. Customization ensures a precise fit and optimal thermal performance for unique project requirements.Q: Where are these ceramic fibre batts manufactured and exported from?

A: The batts are manufactured, supplied, and exported from India, ensuring adherence to international quality standards and supporting global project requirements.Q: What benefits do these batts offer compared to traditional insulation materials?

A: They feature high temperature resistance, superior compressive strength, low water absorption, lightweight construction, and chemical stability. This combination ensures energy efficiency, reduced maintenance, and longer service life in demanding thermal environments.Q: How do I determine the suitable load capacity for a specific application?

A: Load capacity varies depending on the batts dimensions and intended use. It is crucial to consult with the manufacturer to validate the appropriate load capacity based on the specific installation parameters.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plain Batts Category

Refractory Batts

Minimum Order Quantity : 100

Material : High Alumina Refractory

Capacity : Designed for heavyduty furnace use

Style : Rectangular, Flat, Slab

Automation Grade : Manual

Operating Temperature : Up to 1700C

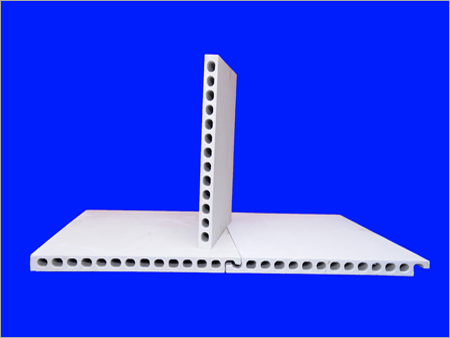

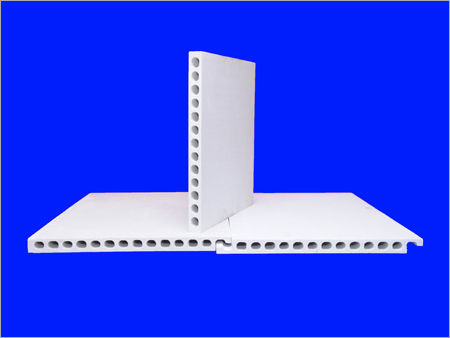

Extruded Batts With Interlock

Minimum Order Quantity : 1 Number

Material : Extruded ceramic fiber

Capacity : Custom sizes available

Style : Interlock batts

Automation Grade : Manual installation

Operating Temperature : Up to 1260C

White Saggar Tray

Minimum Order Quantity : 1 Number

Material : Highquality Ceramic

Capacity : Custom/Varies by tray size

Style : Rectangular

Automation Grade : Manual

Operating Temperature : Up to 1350C

Cordierite Batts

Minimum Order Quantity : 100

Material : Cordierite Ceramic

Capacity : Varies as per size (Custom Sizes Available)

Style : Rectangular/Slab Batts

Automation Grade : Manual/Nonautomated

Operating Temperature : Up to 1320C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry