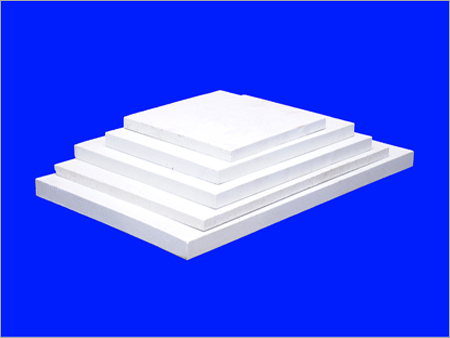

Refractory Batts

Refractory Batts Specification

- Automation Grade

- Manual

- Features

- Corrosion Resistant, Wear Resistant, Precision Dimension

- Surface Treatment

- Smooth Cast Finish

- Load Capacity

- High, suitable for industrial kiln loads

- Used For

- Supporting and stacking ceramic products during firing

- Pressure Ratings

- Not rated

- Operating Temperature

- Up to 1700C

- Material

- High Alumina Refractory

- Style

- Rectangular, Flat, Slab

- Properties

- Thermal Shock Resistance, High Strength, Good Load-bearing Capacity

- Capacity

- Designed for heavy-duty furnace use

- Condition

- New

- Application

- Kiln Furniture, Furnace Linings, Ceramic Firing Racks

- HSN Code

- 69022000

- Thickness

- 12 mm to 50 mm (Customizable)

- Size

- Standard and custom sizes available

- Density

- 2.3 - 2.6 g/cm³

- MOQ

- 50 Pieces

- Water Absorption

- Less than 3%

- Packaging

- Export Quality Wooden Crates

- Color

- Cream / Light Brown

- Shape

- Rectangular / Custom

- Porosity

- Low

Refractory Batts Trade Information

- Minimum Order Quantity

- 100 Number

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Refractory Batts

Having fine finish, accurate dimensions and sturdy design, the provided Pressed Batts are highly demanded among our clients. These batts are highly acknowledged in furniture and home furnishing industries for forming or designing different kinds of furniture. The offered batts manufactured using the best quality clay and sophisticated techniques. In addition, we offer these Pressed Batts to our clients at pocket friendly rates.Superior Load-Bearing and Thermal Resistance

Designed for industrial applications, our refractory batts offer robust load-bearing capability and remarkable resistance to thermal shock. Their precision dimensions, combined with a smooth surface finish, ensure stability and even support for ceramic products in high-temperature processing environments. These qualities enable consistent performance in kilns and furnaces operating up to 1700C.

Customizable Sizes for Versatile Applications

We accommodate a wide variety of requirements, providing refractory batts in both standard and customized dimensions. Whether your needs are for rectangular, flat, or customized slab shapes, we offer seamless solutions for kiln furniture, ceramic firing racks, or furnace linings. Thickness and sizes can be tailored for your specific industrial setup.

FAQs of Refractory Batts:

Q: How are Refractory Batts with high alumina composition manufactured?

A: These batts are produced using carefully selected high alumina materials, shaped into slabs, and precision cast to ensure low porosity and strong mechanical integrity. Post-casting, they undergo firing at high temperatures to achieve thermal shock resistance and a smooth cast finish.Q: What applications are ideal for these Refractory Batts?

A: They are ideally used as kiln furniture, furnace linings, and ceramic firing racks, providing essential support for stacking and firing ceramic products in heavy-duty industrial kilns.Q: When should I consider custom dimensions or thickness for my batts?

A: Custom sizes and thicknesses are recommended when standard dimensions do not adequately meet your kiln or furnace specifications, or for accommodating unique product shapes and load requirements during ceramic processing.Q: Where are these Refractory Batts commonly supplied from?

A: We manufacture and export these batts from India, serving industrial clients globally. Each shipment is packed in export-quality wooden crates to ensure product integrity during international transit.Q: What are the advantages of using low-porosity, high density Refractory Batts?

A: Low-porosity and high-density ensure enhanced load-bearing capacity, minimal water absorption (less than 3%), improved resistance to corrosion and wear, and longer service life in high-temperature environments.Q: How do I maintain and use these batts for optimal kiln performance?

A: Ensure proper placement of batts within the kiln, avoid overloading beyond design limits, and periodically inspect for signs of wear or surface damage. Their corrosion and wear-resistant properties help minimize maintenance needs and ensure consistent firing results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plain Batts Category

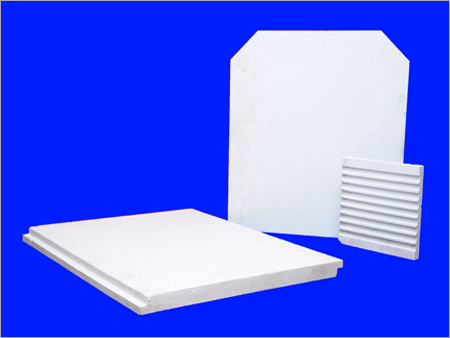

White Saggar Tray

Minimum Order Quantity : 1 Number

Application : Industrial firing, laboratory applications, pottery and ceramic processing

Surface Treatment : Smooth glazed finish

Features : Durable, reusable, heat resistant, nonreactive

Automation Grade : Manual

Properties : Thermal shock resistant, Acid and Alkali resistant

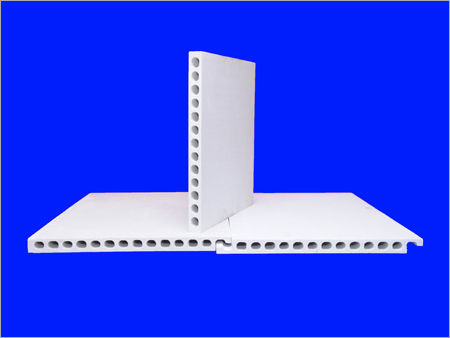

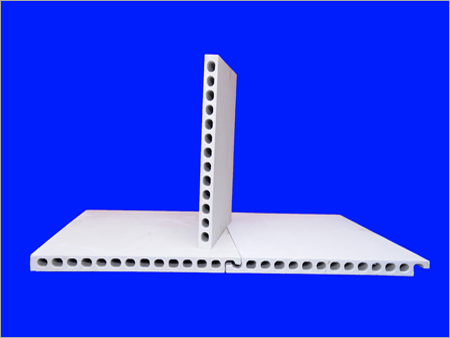

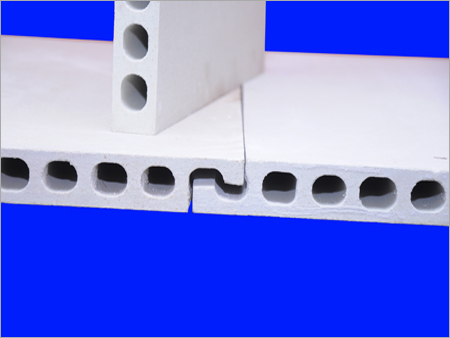

Extruded Batts With Interlock

Minimum Order Quantity : 1 Number

Application : Thermal insulation, Furnace lining, Kiln insulation

Surface Treatment : Smooth surface finish

Features : Lightweight, Low thermal conductivity, Interlock design minimizes gaps

Automation Grade : Manual installation

Properties : High thermal insulation, Fire resistance

Extruded Batts

Minimum Order Quantity : 1 Number

Application : Industrial furnaces, Kilns, Lining for heat treatment plants

Surface Treatment : Smooth finish

Features : Lightweight, Durable, Chemically stable, Easy to install

Automation Grade : Manual

Properties : High temperature resistance, thermal shock stability, low thermal conductivity

Refractory Batts

Minimum Order Quantity : 100

Application : Kiln furniture, kiln shelves, furnace lining

Surface Treatment : Uncoated / plain ceramic finish

Features : Corrosion resistance, low thermal expansion, lightweight

Automation Grade : Manual

Properties : Thermal shock resistance, dimensional accuracy, high mechanical strength

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry