Ceramic Batts

Ceramic Batts Specification

- Automation Grade

- Manual

- Features

- Long life, good thermal stability, corrosion resistant

- Operating Temperature

- Up to 1500C

- Surface Treatment

- Natural finish

- Used For

- Supporting ware during firing in kilns

- Load Capacity

- Varies as per size and thickness

- Material

- Ceramic

- Style

- Rectangular

- Properties

- High strength, thermal shock resistance

- Capacity

- Customizable

- Condition

- New

- Application

- Kiln furniture, ceramic industry

- Color

- Light grey to white

- Customizable Sizes

- Available per customer requirements

- Density

- Around 2.3 - 2.6 g/cm³

- Packing Type

- Corrugated boxes / wooden crates

- Shape

- Flat, rectangular batts

- Edge Type

- Smooth, precision cut

- Thermal Expansion

- Low

- Usage Life

- Multiple kiln cycles depending on process

- Thickness

- Typically ranges from 10 mm to 30 mm

- Water Absorption

- Less than 1%

Ceramic Batts Trade Information

- Minimum Order Quantity

- 100 Number

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

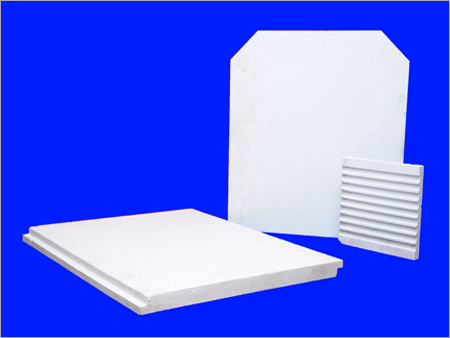

About Ceramic Batts

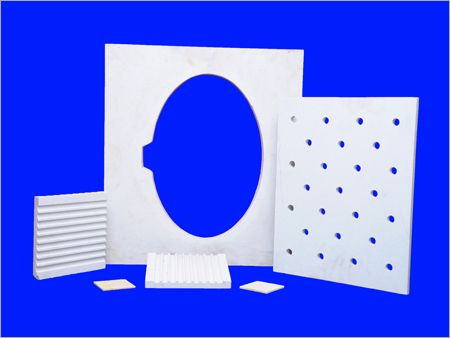

Wash Basin Setter Perforated Batt is designed to mould the wash basin in kiln during firing. It is designed from high quality ceramic and other raw materials to add strength and sturdiness. This is designed in precise dimensions t o provide support as well as maintain the shape of the wash basins. It is designed to withstand high temperatures with its high purity, shock resistant design and maximum durability. This comes with optimum thickness to provode complete protection to the materials.

Features of Wash Basin Setter Perforated Batt:

- Withstand static and thermal loads

- Ensure to provide reliable support and seal to materials

- Maximum durability and heard-wearing design

- No cracks, damage and wear for years

Engineered for High-Temperature Performance

Ceramic Batts are constructed to operate reliably at temperatures up to 1500C. Their low thermal expansion and robust structure make them a dependable component in the kiln environment, reducing risks of breakage or deformation even after repeated firing. This superior heat resistance aids in consistent ceramic production outcomes.

Adaptable Solutions for the Ceramic Industry

Designed with high versatility, these ceramic batts feature customizable sizes, allowing perfect fit for diverse kiln setups and ware shapes. Whether used in large-scale manufacturing or specialty ceramics, their smooth edges and tailored dimensions facilitate efficient stacking and arrangement, optimizing kiln space and process flow.

Exceptional Durability and Efficiency

Manufactured from high-density ceramics with a natural finish, these batts deliver extended service life. Their resistance to corrosion, minimal water absorption, and ability to withstand thermal shocks ensure they support ware through multiple cycles, resulting in cost savings and reduced downtime for the operator.

FAQs of Ceramic Batts:

Q: How should ceramic batts be positioned inside a kiln for optimal support?

A: Ceramic batts should be placed flat and evenly spaced inside the kiln, ensuring full support under ware without excessive overlap. Proper arrangement maximizes airflow and heat distribution, which helps prevent cracking and uneven firing.Q: What benefits do ceramic batts provide compared to other kiln furniture materials?

A: Ceramic batts offer high strength, excellent thermal shock resistance, and low thermal expansion, making them less prone to cracking or warping. Their low water absorption and corrosion resistance result in extended usage life, especially in high-temperature kiln cycles.Q: When should I replace ceramic batts in my kiln?

A: Replacement is recommended when significant warping, deep cracks, or excessive surface wear occur, typically after numerous firing cycles, depending on usage conditions. Regular inspection helps maintain safety and consistent firing quality.Q: Where are these ceramic batts commonly used?

A: These batts are widely used across the ceramic industry, particularly in kilns for supporting and separating ware during firing. They are suitable for use in both industrial and artisan kilns thanks to their customizable sizes.Q: What is the manufacturing process for these ceramic batts?

A: The batts are formed from high-density ceramic material, shaped into flat rectangular forms, and finished with precision-cut edges. They undergo firing at high temperatures to achieve the required strength and thermal properties before undergoing quality checks and packaging.Q: How does the low water absorption benefit kiln operations?

A: With less than 1% water absorption, these batts reduce the risks of moisture-related defects or thermal stress during firing. This ensures reliable operation and consistent performance throughout their usage life.Q: What customization options are available for ceramic batts?

A: Sizes and thicknesses can be tailored to specific customer requirements, with various packing solutions such as corrugated boxes or wooden crates, ensuring suitability for diverse kiln configurations and shipping needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plain Batts Category

Saggar Tray With Cover

Application : Industrial Firing, Lab Applications

Automation Grade : Manual

Capacity : Medium to Large (customizable)

Material : HighQuality Clay Ceramic

Operating Temperature : Up to 1350C

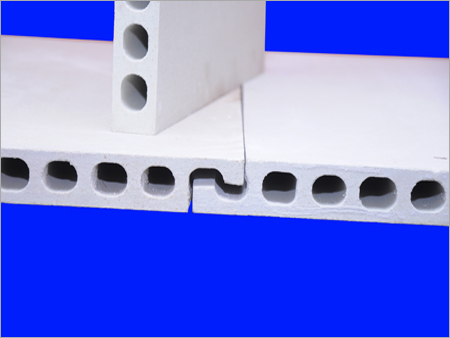

Interlock Extruded Batts

Minimum Order Quantity : 100

Application : Industrial Insulation, Building Insulation, Furnace Lining

Automation Grade : Manual

Capacity : Custom Sizes Available

Material : Mineral Wool / Rockwool

Operating Temperature : Up to 750C

Extruded Batts

Minimum Order Quantity : 1 Number

Application : Industrial furnaces, Kilns, Lining for heat treatment plants

Automation Grade : Manual

Capacity : Custom sizes available

Material : Ceramic Fibre

Operating Temperature : Up to 1450C

Refractory Batts

Minimum Order Quantity : 100

Application : Kiln furniture, kiln shelves, furnace lining

Automation Grade : Manual

Capacity : Custom sizes available

Material : High alumina refractory ceramic

Operating Temperature : Up to 1500C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry