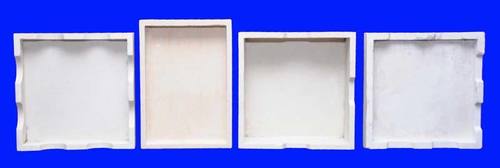

Saggar Tray

Saggar Tray Specification

- Surface Treatment

- Unglazed, smooth finish

- Used For

- Supporting ceramic items during firing

- Features

- Thermal stability, crack resistant, reusable

- Operating Temperature

- Up to 1400C

- Automation Grade

- Manual

- Load Capacity

- Depends on tray dimensions; typically supports several kilograms

- Material

- High Alumina Ceramic

- Style

- Rectangular Tray

- Properties

- Heat resistant, Non-corrosive, Durable

- Capacity

- Multiple wares or specimens (varies by tray size)

- Condition

- New

- Application

- Used in kilns for firing pottery and ceramics

Saggar Tray Trade Information

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Saggar Tray

Saggar Tray :-

Saggar Tray is a small non-flammable tool used during firing in the kiln to support crowns and bridges. It is available in highly pure Al2O3 as well as mullite material to ensure maximum strength. It is able to withstand maximum service temperature of 1800 degree Celsius. In addition, its excellent thermal and shock resistant design makes it ideal to be used for years to come without any abrasion, cracks and damage.

Features of Saggar Tray:

- Does not crack and break

- Ideal to protect ware from open flame, gases and kiln debris

- Easy to clean and maintain

- Available with high purity without any silica contents

Exceptional Heat Resistance and Durability

Constructed from high alumina ceramic, the Saggar Tray endures extreme kiln temperatures up to 1400C. Its thermal stability and crack-resistant design ensure long-lasting performance in demanding firing environments, making it ideal for supporting delicate or heavy ceramic pieces during repeated kiln cycles.

Versatile Design for Multiple Applications

Available in flat rectangular or oval shapes, the Saggar Tray accommodates a variety of wares or specimens. Customizable thickness and size options enable it to meet the specific needs of ceramic manufacturers, artists, and laboratories, providing reliable support for pottery, tiles, and experimental materials.

Engineered for Efficiency and Safety

With smooth, rounded edges and low porosity, the unglazed surface minimizes contamination and simplifies cleaning. Its manual operation and reusable nature contribute to overall cost-effectiveness, while ensuring a safe, consistent firing process from batch to batch.

FAQs of Saggar Tray:

Q: How should the Saggar Tray be used during ceramic firing?

A: Place the Saggar Tray inside the kiln to support ceramic items during the firing process. The tray isolates wares from direct flames and ensures even heating, reducing the risk of breakage or contamination. Arrange items with sufficient spacing to allow for proper heat circulation.Q: What makes the Saggar Tray suitable for high-temperature applications?

A: The high alumina ceramic material grants the tray excellent thermal stability and heat shock resistance. It is engineered to withstand kiln temperatures up to 1400C without cracking, deforming, or corroding, making it highly reliable for intensive firing cycles.Q: When should I opt for a customized size or thickness for my Saggar Tray?

A: Choose custom sizes or thicknesses when your firing load, kiln dimensions, or specific ware requirements differ from standard options. Customization ensures optimal support, stability, and load capacity tailored to your operational needs.Q: Where are Saggar Trays typically used?

A: Saggar Trays are commonly used in pottery studios, ceramic manufacturing plants, research laboratories, and educational facilities throughout India and internationally. They are essential wherever kiln firing of ceramics takes place.Q: What is the process for cleaning and maintaining a Saggar Tray?

A: Allow the tray to cool after firing, then gently brush off any debris or residue. Avoid using water or harsh chemicals, as the unglazed, low-porosity surface prevents most contamination. Store trays in a dry area to maintain their integrity.Q: What benefits does the Saggar Tray offer over traditional kiln furniture?

A: Key advantages include superior heat resistance, low porosity to minimize sticking and contamination, and enhanced durability for repeated reuse. Its smooth, rounded edges also reduce the risk of damaging wares, resulting in fewer production losses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plain Batts Category

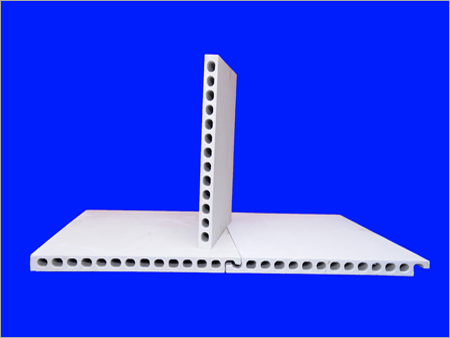

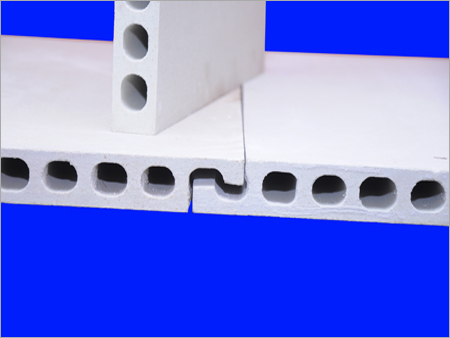

Extruded Batts With Interlock

Minimum Order Quantity : 1 Number

Application : Thermal insulation, Furnace lining, Kiln insulation

Operating Temperature : Up to 1260C

Style : Interlock batts

Condition : New

Surface Treatment : Smooth surface finish

Extruded Batts

Minimum Order Quantity : 1 Number

Application : Industrial furnaces, Kilns, Lining for heat treatment plants

Operating Temperature : Up to 1450C

Style : Extruded Batts

Condition : New

Surface Treatment : Smooth finish

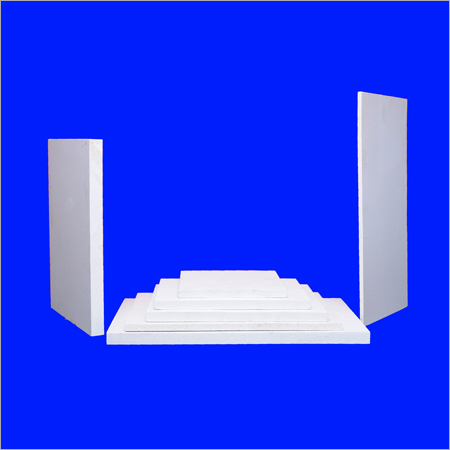

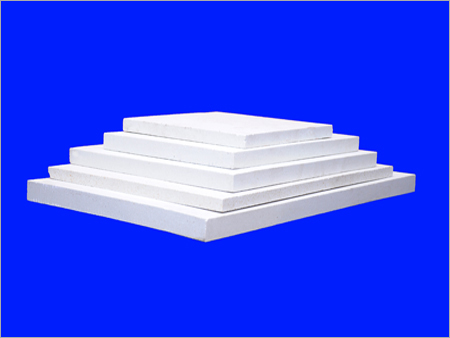

Pressed Batts

Minimum Order Quantity : 100

Application : Thermal and acoustic insulation in buildings, HVAC, industrial plants

Operating Temperature : Up to 250C

Style : Pressed Batts

Condition : New

Surface Treatment : Plain, noncombustible surface

Cordierite Batts

Minimum Order Quantity : 100

Application : Used in kiln furniture, pottery, ceramic firing, and heat treatment

Operating Temperature : Up to 1320C

Style : Rectangular/Slab Batts

Condition : New

Surface Treatment : Uncoated / Natural finish

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry