Interlock Extruded Batts

Interlock Extruded Batts Specification

- Automation Grade

- Manual

- Surface Treatment

- Uncoated / Untreated

- Features

- Non-Combustible, Rigid, High Compressive Strength, Moisture Resistant

- Operating Temperature

- Up to 750C

- Used For

- Thermal and Acoustic Insulation in High Temperature Applications

- Load Capacity

- Dependent on Installation

- Material

- Mineral Wool / Rockwool

- Style

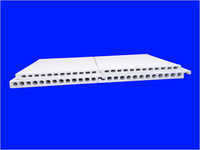

- Interlocked Extruded

- Properties

- Fire Resistant, Sound Absorption, Thermal Insulation

- Capacity

- Custom Sizes Available

- Condition

- New

- Application

- Industrial Insulation, Building Insulation, Furnace Lining

- Heat Expansion

- Low linear expansion coefficient

- Length Range

- Custom (typical 300 mm 1000 mm)

- Chemical Resistance

- High acid and alkali resistance

- Density

- 2.6 - 2.8 g/cm

- Thickness Range

- 12 mm to 50 mm

- Shape

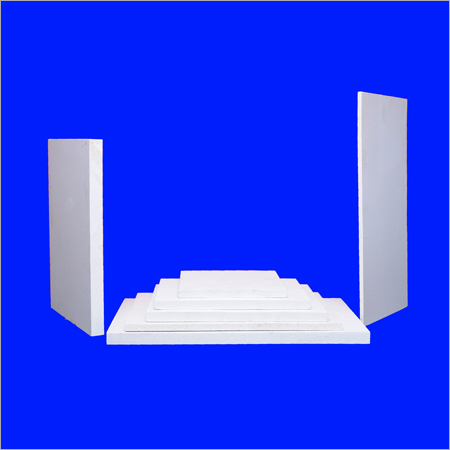

- Batt/Slab

- Porosity

- Low open porosity

- Color

- Light cream

- Module of Rupture

- >50 MPa

- Water Absorption

- <2%

- Width Range

- Custom (typical 200 mm 800 mm)

Interlock Extruded Batts Trade Information

- Minimum Order Quantity

- 100 Number

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Interlock Extruded Batts

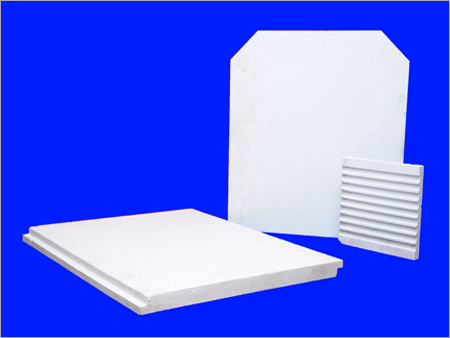

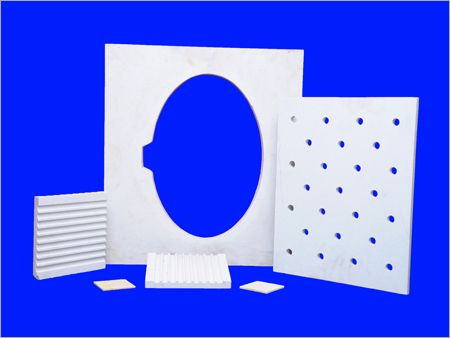

Interlock Extruded Batts are designed with holes running the cross sectional length. They are developed to provide excellent results in the domain of sanitaryware and glass panel industries. Employing modern high pressure vacuum extrusion processes, they are developed before being cut. This process is used in the production to ensure to provide the highest standard of flatness. They are available to impart superior thermal shock resistant to enhance the longevity of insulating firebricks as well as ceramic fibre linings.

Features of Interlock Extruded Batts:

- Can tolerate high working temperature and treatment processes up to 1300oC (2400oF)

- Rapid heating as well as cooling rates

- Low density to save energy in every firing

- Stay stable at high temperatures to ensure no damage

Exceptional Thermal and Acoustic Insulation

Engineered for high-temperature applications, Interlock Extruded Batts deliver outstanding thermal insulation up to 750C and reliable sound absorption. This makes them perfect for both industrial and building environments, such as boiler rooms, furnace linings, and partition walls, where controlling heat and noise is essential.

Designed for Durability and Chemical Resistance

With low open porosity and high acid and alkali resistance, these mineral wool batts maintain their structural integrity and function in corrosive or humid conditions. They are non-combustible, moisture resistant, and possess a high compressive strength, ensuring a long service life in challenging installations.

FAQs of Interlock Extruded Batts:

Q: How are Interlock Extruded Batts typically used in insulation applications?

A: Interlock Extruded Batts are utilized primarily for thermal and acoustic insulation in high-temperature environments, such as industrial equipment, furnace linings, and building partitions. Their rigidity and interlocking design enhance stability and uniform coverage during installation.Q: What benefits do these batts offer compared to other insulation materials?

A: These batts provide superior fire resistance, high compressive strength, and excellent chemical resistance, all crucial for industrial and high-temperature settings. Their low water absorption and non-combustible properties further enhance safety and longevity.Q: When should I choose custom sizes for my insulation project?

A: Custom sizes should be selected when standard dimensions (thickness: 1250 mm, length: 3001000 mm, width: 200800 mm) do not meet your specific installation requirements. Custom sizing ensures precise fitment, reducing material wastage and improving overall performance.Q: Where can Interlock Extruded Batts be installed for optimal results?

A: These batts are ideal for industrial and commercial settingssuch as power plants, manufacturing plants, and large-scale building projectsthat demand high-performance insulation for thermal and acoustic control. Their robust construction also makes them suitable for outdoor or exposed installations.Q: What is the process for installing these batts?

A: Installation typically involves manual placement of the batts into wall, ceiling, or equipment cavities, taking advantage of their rigid and interlocking form. No special treatments are necessary due to their uncoated surfaces, and adjustments can be made on-site to fit specific spaces.Q: Are there any specific storage or handling recommendations?

A: Store the batts in dry conditions to preserve their moisture-resistance properties and avoid compressing them to maintain the products structural integrity. Handle with gloves to minimize irritation from mineral fibers, and cut or shape as needed with common insulation tools.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plain Batts Category

Pressed Batts

Minimum Order Quantity : 100

Condition : New

Load Capacity : Varies as per density and thickness

Used For : Used for insulation in walls, roofs, and industrial enclosures

Operating Temperature : Up to 250C

Material : Resin Bonded Glass Wool

Refractory Batts

Minimum Order Quantity : 100

Condition : New

Load Capacity : High load bearing capacity

Used For : Support and shelving of ware during firing

Operating Temperature : Up to 1500C

Material : High alumina refractory ceramic

Ceramic Batts

Minimum Order Quantity : 100

Condition : New

Load Capacity : Varies as per size and thickness

Used For : Supporting ware during firing in kilns

Operating Temperature : Up to 1500C

Material : Ceramic

Open Saggar Tray

Condition : New

Load Capacity : Depends on design; supports moderate to heavy loads

Used For : High temperature firing, sintering materials

Operating Temperature : Up to 1600C

Material : High Alumina Ceramic

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry