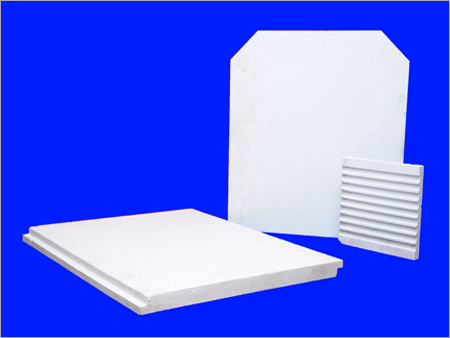

Refractory Batts

Refractory Batts Specification

- Automation Grade

- Manual

- Features

- Corrosion resistance, low thermal expansion, lightweight

- Load Capacity

- High load bearing capacity

- Operating Temperature

- Up to 1500C

- Used For

- Support and shelving of ware during firing

- Surface Treatment

- Uncoated / plain ceramic finish

- Material

- High alumina refractory ceramic

- Style

- Rectangular Batts

- Properties

- Thermal shock resistance, dimensional accuracy, high mechanical strength

- Capacity

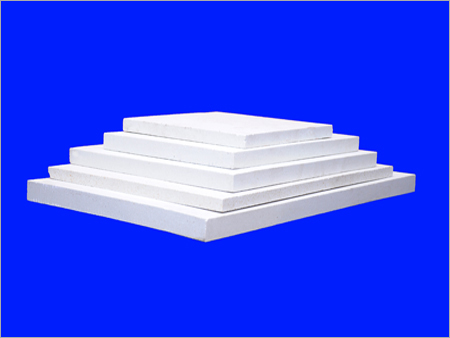

- Custom sizes available

- Condition

- New

- Application

- Kiln furniture, kiln shelves, furnace lining

- Density

- 1.82.6 g/cm

- Shape

- Rectangular or custom shapes available

- Packaging

- Wooden crates or palletized for transport

- Thickness Range

- 10 mm to 40 mm

- Compressive Strength

- High; designed for heavy kiln loads

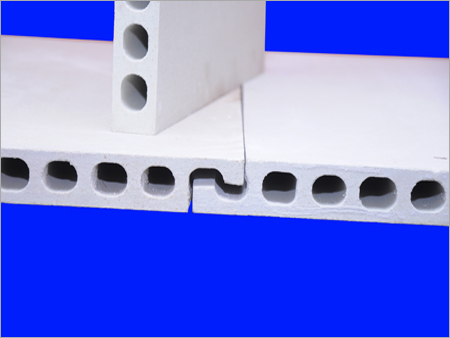

- Edge Type

- Square or beveled edges as required

- Porosity

- Low, typically less than 20%

- Bulk Weight

- Depends on size and thickness

- Moisture Absorption

- Negligible

- Chemical Resistance

- Excellent against acids and alkalis

- Thermal Shock Resistance

- Superior

- Color

- Light gray to beige

Refractory Batts Trade Information

- Minimum Order Quantity

- 100 Number

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Refractory Batts

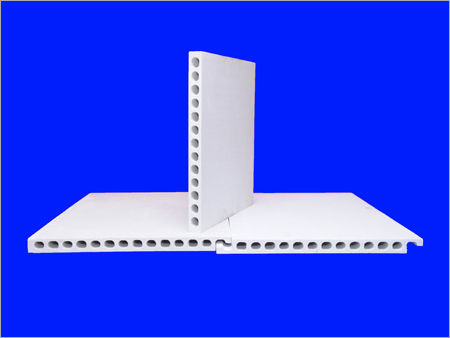

The durability of the kiln depends on the usage conditions and robustness standards of the batts. This Corner Cut Rib Step Batts are designed to meet every kiln atmosphere with its ability to withstand high temperatures during firing. They are developed to fit the needs of different firing curve as well as cooling methods. Their light weight yet maximum sturdiness ensure to provide the best performance that preserves the quality, shape and durability of the material.

Features of Corner Cut Rib Step Batts:

- Maximum purity with silica content free design

- Ability to withstand temperatures up to 1750 degree C

- High-end surface finishing with light weight

- Thermally shock resistant design

Superior Load-Bearing Capacity and Dimensional Accuracy

These refractory batts are engineered for heavy-duty industrial applications, boasting high compressive strength and precise dimensions. They efficiently withstand substantial kiln loads and maintain structural integrity during firing cycles. The batts minimal moisture absorption and accurate sizing ensure consistent support, reducing the risk of warping or product defects. Their low porosity and lightweight design further optimize kiln performance and energy efficiency.

Outstanding Chemical and Thermal Shock Resistance

Manufactured from high-alumina ceramic materials, the batts exhibit excellent resistance to acids and alkalis, making them suitable for diverse firing environments. Their superior thermal shock resistance allows safe and repeated exposure to rapid temperature fluctuations, minimizing the risk of cracking. With an operating temperature of up to 1500C, these batts serve reliably in both kilns and furnace linings, delivering long-lasting performance and protection for ware.

Customizable Options for Varied Industrial Needs

These batts can be tailored in terms of size, thickness, shape, and edge finish (square or beveled) to match specific kiln or furnace requirements. Whether required for customized shelving, support systems, or unique lining configurations, manufacturers in India provide solutions that align with capacity and application needs. Delivered in robust wooden crates or palletized packaging, each batt assures safe transport and easy handling on site.

FAQs of Refractory Batts:

Q: How are refractory batts typically used in kiln and furnace operations?

A: Refractory batts are primarily used as support shelves or kiln furniture during the firing process, providing stable and durable surfaces for ware, ceramics, or other materials. They enable efficient heat transfer and uniform load distribution, ensuring consistent results and protecting items during high-temperature cycles.Q: What benefits do high alumina refractory batts offer for industrial applications?

A: High alumina refractory batts deliver several advantages, including excellent thermal shock resistance, high compressive strength for heavy loads, resistance to chemical attack by acids and alkalis, and minimal moisture absorption. These properties ensure reliable, long-term performance and reduce maintenance needs in industrial kilns and furnaces.Q: When should custom-shaped refractory batts be used?

A: Custom-shaped refractory batts are recommended when standard rectangular forms do not fit your kiln or furnaces unique configuration or when specialized shelf or lining arrangements are required. Customization ensures optimal support, efficient use of space, and alignment with specific process requirements.Q: Where are these refractory batts manufactured and supplied from?

A: These batts are manufactured, exported, and supplied by specialist refractory producers based in India, who utilize advanced techniques to ensure quality, dimensional accuracy, and reliable thermal properties. International shipping and robust packaging facilitate safe global distribution.Q: What is the process for ordering custom sizes and shapes for refractory batts?

A: To order custom batts, clients typically consult with the manufacturer to specify required dimensions, thickness, shape, and edge design. After confirming application needs and operating conditions, the manufacturer provides tailored solutions and arranges appropriate packaging for safe transport.Q: What makes these refractory batts suitable for high-load kiln applications?

A: Their high compressive strength, density, and dimensional stability make them ideal for supporting heavy loads during firing. Engineered to resist deformation and breakage, they reliably support large batches of ware or materials at temperatures up to 1500C.Q: How does the low porosity of these batts benefit kiln performance?

A: Low porosity reduces the risk of thermal conductivity inconsistencies, limits moisture absorption, and improves the overall energy efficiency of the kiln. This enhances durability, as batts are less likely to suffer from structural degradation or heat loss over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plain Batts Category

White Saggar Tray

Minimum Order Quantity : 1 Number

Features : Durable, reusable, heat resistant, nonreactive

Automation Grade : Manual

Capacity : Custom/Varies by tray size

Operating Temperature : Up to 1350C

Load Capacity : Depends on dimension & kiln; typically 510 kg

Extruded Batts

Minimum Order Quantity : 1 Number

Features : Lightweight, Durable, Chemically stable, Easy to install

Automation Grade : Manual

Capacity : Custom sizes available

Operating Temperature : Up to 1450C

Load Capacity : Depends on dimensions, consult manufacturer

Cordierite Batts

Minimum Order Quantity : 100

Features : Lightweight, Durable, Good resistance to chemical attack, Long service life

Automation Grade : Manual/Nonautomated

Capacity : Varies as per size (Custom Sizes Available)

Operating Temperature : Up to 1320C

Load Capacity : Depends on size and thickness

Open Saggar Tray

Features : Open design for improved air flow, high thermal stability, corrosion resistant

Automation Grade : Manual

Capacity : Varies by size, customisable

Operating Temperature : Up to 1600C

Load Capacity : Depends on design; supports moderate to heavy loads

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry