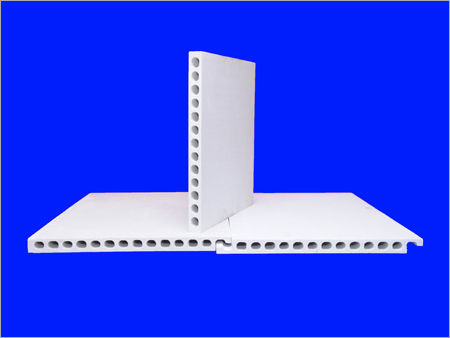

Open Saggar Tray

Open Saggar Tray Specification

- Surface Treatment

- Smooth, glazed finish

- Automation Grade

- Manual

- Operating Temperature

- Up to 1600C

- Used For

- High temperature firing, sintering materials

- Features

- Open design for improved air flow, high thermal stability, corrosion resistant

- Load Capacity

- Depends on design; supports moderate to heavy loads

- Material

- High Alumina Ceramic

- Style

- Rectangular Open Tray

- Properties

- Thermal shock resistant, High strength, Durable

- Capacity

- Varies by size, customisable

- Condition

- New

- Application

- Used in ceramic firing, laboratory, and industrial kilns

- Shape

- Rectangular

- Usage Environment

- Oxidizing and Reducing Atmospheres

- Packing Type

- Carton or Wooden Box for Safe Transit

- Edge Type

- Raised Edges for Secure Handling

- Compatibility

- Suitable for Various Kiln Types

- Weight

- 4.2 kg (approximate)

- Color

- Off-White / Beige

- Life Expectancy

- 150+ Cycles Under Normal Conditions

- Dimensions

- 350 mm x 230 mm x 60 mm (LxWxH, approximate)

Open Saggar Tray Trade Information

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Open Saggar Tray

Open Saggar Tray is widely used in the domain of firing of pottery. This is a kind of kiln furniture developed in the design of ceramic boxlike container. It is developed to provide complete protection to the ware from any kind of damage caused due to high temperatures. This is designed from optimum quality raw materials such as mullite ceramic silicon carbide, alumina ceramic, cordierite ceramic, etc. This is designed to provide to protect a range of ware from gases, kiln debris, high temperature etc.

Features of Open Saggar Tray:

- Available in different sizes to provide protection to materials during firing

- Excellent thermal shock resistant design

- Maximum sturdiness, strength and durability

- Minimum abrasion and damage

High Durability & Performance

Crafted from high alumina ceramic, the Open Saggar Tray delivers excellent strength and resilience. Its thermal shock resistance and corrosion-proof surface are engineered to withstand repeated use at high temperatures, ensuring dependable performance over 150 cycles. The robust structure supports heavy loads across a range of industrial and laboratory settings.

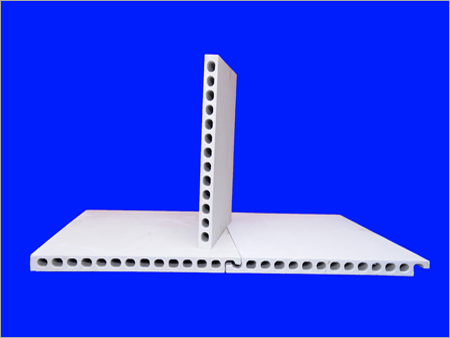

Optimal Design for Industrial Needs

With its open, rectangular design, the tray facilitates improved air flow during firing or sintering, ensuring uniform heat distribution. Raised edges enable safe and secure handling, while the smooth, glazed finish simplifies cleaning and minimizes contamination. Its compatibility with different kiln types makes it ideal for diverse high-temperature applications.

FAQs of Open Saggar Tray:

Q: How should the Open Saggar Tray be used during high temperature firing?

A: Place the Open Saggar Tray inside the kiln with sufficient space around it to ensure proper air flow. Position ceramic wares or materials within the tray, ensuring the load does not exceed its capacity. Its open design and thermal properties make it suitable for both oxidizing and reducing atmospheres.Q: What benefits does the high alumina ceramic material provide?

A: High alumina ceramics offer superior thermal shock resistance, high mechanical strength, and excellent durability. These properties enable the tray to withstand frequent heating and cooling cycles, resist chemical corrosion, and support moderate to heavy loads in industrial settings.Q: When is it recommended to replace the Open Saggar Tray?

A: Under normal operational conditions, the tray provides a life expectancy of over 150 cycles. Inspection for cracks, excessive wear, or surface damage is advised after each use. Replace the tray when these signs become apparent to maintain optimal safety and performance.Q: Where can the Open Saggar Tray be utilized effectively?

A: The tray is versatile and suitable for ceramic firing, laboratory experiments, and various industrial kiln applications. Its compatibility with different kiln types makes it an excellent choice for manufacturers, material science labs, and high-temperature processing environments.Q: What is the process for ordering custom sizes of this tray?

A: To obtain a customised Open Saggar Tray, specify the required capacity or dimensions when placing your order. The manufacturer offers flexibility in tray size and design to meet specific operational needs for different applications.Q: How does the raised edge design benefit handling and safety?

A: The raised edges of the tray provide extra grip and protection when handling hot or heavy loads, minimizing the risk of accidental spillage or injury. This feature also ensures stable stacking and transport of ware within kiln environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

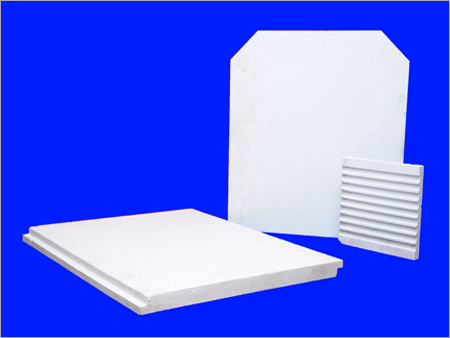

More Products in Plain Batts Category

White Saggar Tray

Minimum Order Quantity : 1 Number

Material : Highquality Ceramic

Capacity : Custom/Varies by tray size

Features : Durable, reusable, heat resistant, nonreactive

Used For : Holding ceramic wares during hightemperature firing in kiln

Application : Industrial firing, laboratory applications, pottery and ceramic processing

Extruded Batts With Interlock

Minimum Order Quantity : 1 Number

Material : Extruded ceramic fiber

Capacity : Custom sizes available

Features : Lightweight, Low thermal conductivity, Interlock design minimizes gaps

Used For : Industrial heat insulation, Energy saving

Application : Thermal insulation, Furnace lining, Kiln insulation

Interlock Extruded Batts

Minimum Order Quantity : 100

Material : Mineral Wool / Rockwool

Capacity : Custom Sizes Available

Features : NonCombustible, Rigid, High Compressive Strength, Moisture Resistant

Used For : Thermal and Acoustic Insulation in High Temperature Applications

Application : Industrial Insulation, Building Insulation, Furnace Lining

Refractory Batts

Minimum Order Quantity : 100

Material : High alumina refractory ceramic

Capacity : Custom sizes available

Features : Corrosion resistance, low thermal expansion, lightweight

Used For : Support and shelving of ware during firing

Application : Kiln furniture, kiln shelves, furnace lining

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry