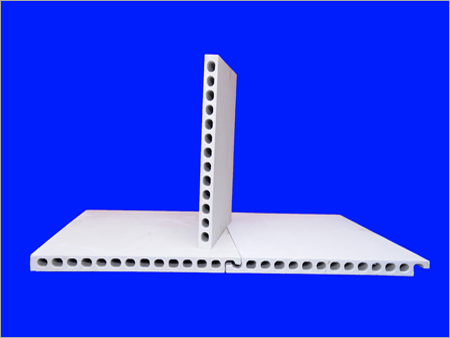

Extruded Batts With Interlock

Extruded Batts With Interlock Specification

- Surface Treatment

- Smooth surface finish

- Load Capacity

- Designed for heavy duty lining applications

- Used For

- Industrial heat insulation, Energy saving

- Features

- Lightweight, Low thermal conductivity, Interlock design minimizes gaps

- Operating Temperature

- Up to 1260C

- Automation Grade

- Manual installation

- Pressure Ratings

- Suitable for high pressure resistant lining

- Material

- Extruded ceramic fiber

- Style

- Interlock batts

- Properties

- High thermal insulation, Fire resistance

- Capacity

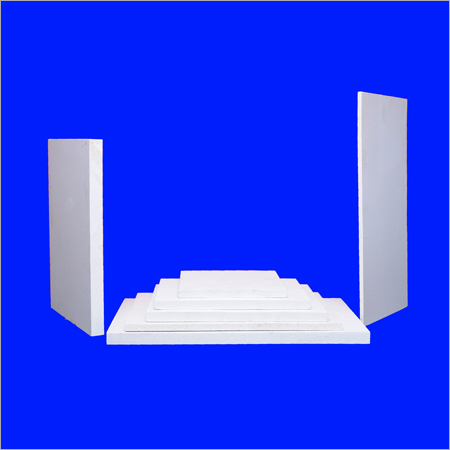

- Custom sizes available

- Condition

- New

- Application

- Thermal insulation, Furnace lining, Kiln insulation

- Moisture Absorption

- Very Low

- Shape

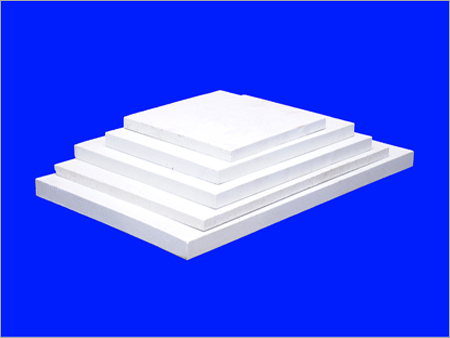

- Rectangular with interlock design

- Edge Type

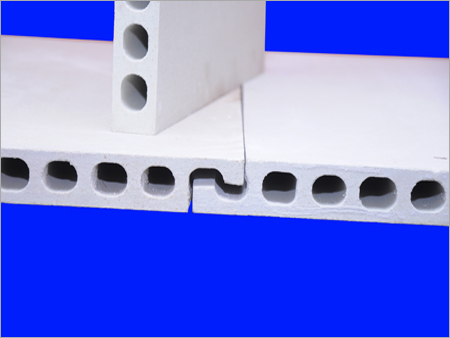

- Precision Machined Interlocking Edges

- Thickness

- Standard and custom thicknesses

- Temperature Uniformity

- Ensures even heat distribution

- Density

- 2.22.4 g/cm

- Thermal Expansion

- Low, for minimal warping

- Color

- Beige / Light Brown

- Installation Type

- Dry Set, Interlocking Placement

- Chemical Resistance

- High, resistant to kiln atmospheres

- Standards

- As per industrial norms

Extruded Batts With Interlock Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Extruded Batts With Interlock

Features of Extruded Batts With Interlock:

- Can be used at high heat treatment processes

- Extremely resistant to thermal shock cracking

- Stable at high temperatures without degradation

- Low density and high durability

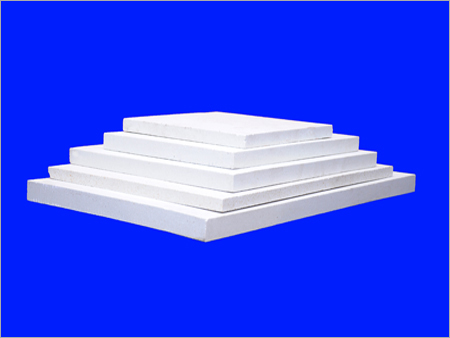

Precision Interlocking for Seamless Insulation

Each batt features expertly engineered interlocking edges, ensuring tight joints and reducing heat loss through gaps. This design not only enhances temperature uniformity but also supports mechanical stability under high pressure. Perfect for upgrading furnaces, kilns, and industrial linings, these batts combine efficiency with ease of installation.

Robust Ceramic Fiber Construction

Manufactured with extruded ceramic fiber, these batts deliver outstanding thermal insulation, fire resistance, and chemical durability. The density of 2.22.4 g/cm allows them to withstand routine and heavy-duty industrial conditions. Their low moisture absorption and smooth surface add to their longevity and performance.

Versatile Sizing and Installation

Available in both standard and custom thicknesses, the batts cater to diverse industrial requirements. The dry-set, manual installation process means minimal downtime and flexibility for various lining configurations. They are an excellent choice for energy-saving insulation in high-temperature applications, ensuring operational efficiency.

FAQs of Extruded Batts With Interlock:

Q: How are the Extruded Batts With Interlock installed?

A: These batts feature a dry-set, manual installation process. The precision-machined, interlocking edges allow for secure placement, ensuring stability and minimizing gaps without the need for adhesives or complex fittings.Q: What applications are ideal for these interlock batts?

A: They are perfectly suited for industrial furnace lining, kiln insulation, and general high-temperature heat insulation. Their durability and energy-saving properties make them a prime choice for any setting requiring robust, heavy-duty thermal insulation.Q: When should I choose custom thickness or size options?

A: Opt for custom dimensions when specific lining requirements or unique furnace/kiln architectures demand precise fitting. Custom sizes ensure optimal insulation coverage and performance in specialized industrial applications.Q: Where do these interlock batts provide the most benefit?

A: Their benefits stand out in industrial environments that require consistent temperature control, heavy-duty lining, and energy efficiencysuch as steel plants, ceramics kilns, and high-pressure processing chambers.Q: What makes the interlock design advantageous over standard batts?

A: The interlock design tightly joins each batt, significantly reducing gaps that can cause heat escapes or thermal inconsistencies. This yields improved heat retention, uniform temperature distribution, and added structural stability.Q: How does the material composition support high-performance insulation?

A: Constructed from extruded ceramic fiber with a density of 2.22.4 g/cm, these batts offer high thermal and fire resistance. Their chemical stability and low moisture absorption enhance long-term durability in harsh industrial atmospheres.Q: What is the benefit of low thermal expansion and high chemical resistance?

A: Low thermal expansion minimizes warping or distortion at elevated temperatures, while high chemical resistance ensures longevity and structural integrity in aggressive kiln environments, promoting reliable insulation performance over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plain Batts Category

Refractory Batts

Minimum Order Quantity : 100

Style : Rectangular, Flat, Slab

Operating Temperature : Up to 1700C

Features : Corrosion Resistant, Wear Resistant, Precision Dimension

Load Capacity : High, suitable for industrial kiln loads

Used For : Supporting and stacking ceramic products during firing

Cordierite Batts

Minimum Order Quantity : 100

Style : Rectangular/Slab Batts

Operating Temperature : Up to 1320C

Features : Lightweight, Durable, Good resistance to chemical attack, Long service life

Load Capacity : Depends on size and thickness

Used For : Supporting ceramic wares during firing

Extruded Batts

Minimum Order Quantity : 1 Number

Style : Extruded Batts

Operating Temperature : Up to 1450C

Features : Lightweight, Durable, Chemically stable, Easy to install

Load Capacity : Depends on dimensions, consult manufacturer

Used For : Thermal insulation in high temperature processes

Pressed Batts

Minimum Order Quantity : 100

Style : Pressed Batts

Operating Temperature : Up to 250C

Features : Light weight, easy to install, water repellent, noncombustible, ecofriendly

Load Capacity : Varies as per density and thickness

Used For : Used for insulation in walls, roofs, and industrial enclosures

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry