Cordierite Batts

Cordierite Batts Specification

- Operating Temperature

- Up to 1320C

- Load Capacity

- Depends on size and thickness

- Used For

- Supporting ceramic wares during firing

- Features

- Lightweight, Durable, Good resistance to chemical attack, Long service life

- Automation Grade

- Manual/Non-automated

- Surface Treatment

- Uncoated / Natural finish

- Material

- Cordierite Ceramic

- Style

- Rectangular/Slab Batts

- Properties

- High thermal shock resistance, Low thermal expansion, Excellent mechanical strength

- Capacity

- Varies as per size (Custom Sizes Available)

- Condition

- New

- Application

- Used in kiln furniture, pottery, ceramic firing, and heat treatment

- Water Absorption

- 45%

- Maximum Firing Cycles

- Up to 1000 cycles

- Color

- Light beige/grey

- Shape

- Rectangular (custom available)

- Flexural Strength

- >8 MPa

- Thickness Range

- 10-40 mm

- Density

- 1.8-2.0 g/cm

- Porosity

- Typically 28-38%

- Thermal Conductivity

- Low

Cordierite Batts Trade Information

- Minimum Order Quantity

- 100 Number

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

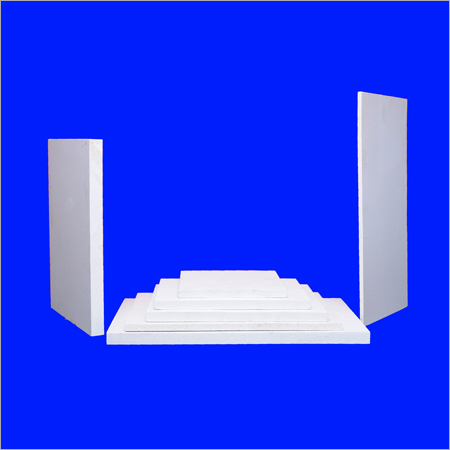

About Cordierite Batts

Offered Cordierite Batts are best to be used in various industries such as furniture, sanitary, construction and metal working. These batts are manufactured using the finest grade clay and pioneering techniques. Known for excellent heat tolerant, extended durability and supreme finish, these batts are used for rendering excellent support to an item. Moreover, the provided Cordierite Batts can be availed by our esteemed patrons at cost effective rates.High Durability and Thermal Performance

Cordierite Batts offer remarkable durability and longevity, engineered to endure thermal cycling and high-temperature firing up to 1320C. Their low thermal expansion and high shock resistance ensure minimal warping, making them ideal for repeated use in industrial and craft kiln settings. The lightweight yet robust nature increases handling efficiency and reduces operational wear.

Customizable for Versatile Applications

Available in standard rectangular slabs or tailored to unique specifications, these batts serve as critical kiln furniture across ceramics, pottery, and heat treatment operations. Their adaptable design and variant thicknesses (1040 mm) let users select or order dimensions optimal for their production scale and configuration.

Superior Material Properties for Kiln Stability

Manufactured from high-quality cordierite ceramic, these batts combine low thermal conductivity with excellent mechanical strength and chemical resilience. The uncoated natural finish promotes clean, consistent firing, supporting both mass production and artisanal needs for high-precision outcomes.

FAQs of Cordierite Batts:

Q: How are Cordierite Batts typically used in ceramic or pottery kilns?

A: Cordierite Batts are primarily used as support platforms within kilns, providing stable and flat surfaces for stacking ceramic wares during the firing process. Their high thermal shock resistance and low thermal expansion help protect delicate items from cracking or stress throughout repeated heating cycles.Q: What benefits do Cordierite Batts offer over other kiln furniture materials?

A: Cordierite Batts offer superior resistance to thermal shock, low thermal expansion, and excellent mechanical strength, making them less likely to warp or crack. They have a lightweight but durable construction, offer long service life (up to 1000 firing cycles), and demonstrate good chemical resistance, translating to reduced maintenance and operational costs.Q: When should Cordierite Batts be replaced in a kiln setup?

A: Cordierite Batts should be replaced when visible signs of structural fatigue, excessive warping, or cracks appear, or when their mechanical stability is compromised due to prolonged use. Under normal operating conditions, they can withstand up to 1000 firing cycles before replacement is required.Q: Where can custom-sized Cordierite Batts be sourced?

A: Custom-sized Cordierite Batts are available directly from exporters, manufacturers, or suppliers in India offering the product. Specifications such as thickness, length, and width can be tailored to fit different kiln dimensions and specific process requirements.Q: What is the process for installing Cordierite Batts in a kiln?

A: Installation is manual and involves arranging the batts evenly on kiln supports or shelf posts. Proper placement ensures optimal load distribution and supports the weight of ceramic wares without exceeding the specified load capacities for each batt size and thickness.Q: How does the porosity of Cordierite Batts impact their usage?

A: The typical 2838% porosity of Cordierite Batts provides good thermal insulation and reduces heat in the kiln structure. This characteristic helps prevent heat loss, ensuring energy efficiency and consistent firing results while supporting a wide variety of ceramic ware types.Q: What maintenance or cleaning is recommended for Cordierite Batts?

A: Cordierite Batts should be allowed to cool gradually, then gently brushed or wiped to remove any glaze drips or debris. Avoid using water or harsh chemicals, as these can penetrate the porous structure and impair performance during subsequent firings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plain Batts Category

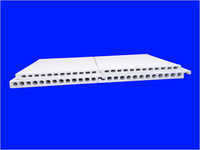

Extruded Batts

Minimum Order Quantity : 1 Number

Operating Temperature : Up to 1450C

Capacity : Custom sizes available

Properties : High temperature resistance, thermal shock stability, low thermal conductivity

Used For : Thermal insulation in high temperature processes

Load Capacity : Depends on dimensions, consult manufacturer

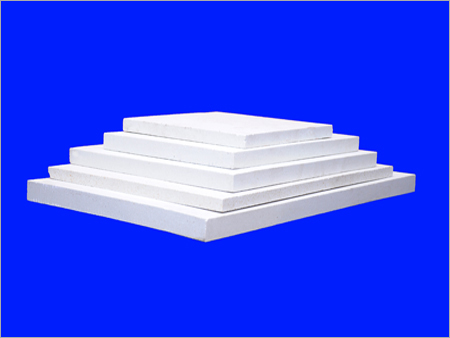

Pressed Batts

Minimum Order Quantity : 100

Operating Temperature : Up to 250C

Capacity : Custom sizes available

Properties : Excellent thermal insulation, sound absorption, fire resistance

Used For : Used for insulation in walls, roofs, and industrial enclosures

Load Capacity : Varies as per density and thickness

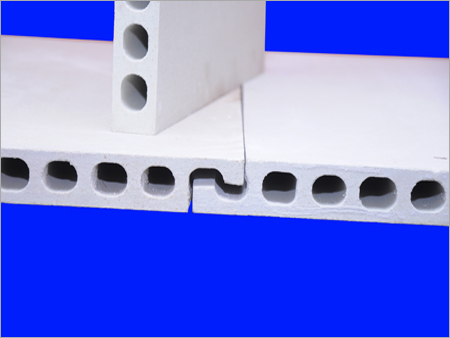

Interlock Extruded Batts

Minimum Order Quantity : 100

Operating Temperature : Up to 750C

Capacity : Custom Sizes Available

Properties : Fire Resistant, Sound Absorption, Thermal Insulation

Used For : Thermal and Acoustic Insulation in High Temperature Applications

Load Capacity : Dependent on Installation

Open Saggar Tray

Operating Temperature : Up to 1600C

Capacity : Varies by size, customisable

Properties : Thermal shock resistant, High strength, Durable

Used For : High temperature firing, sintering materials

Load Capacity : Depends on design; supports moderate to heavy loads

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry