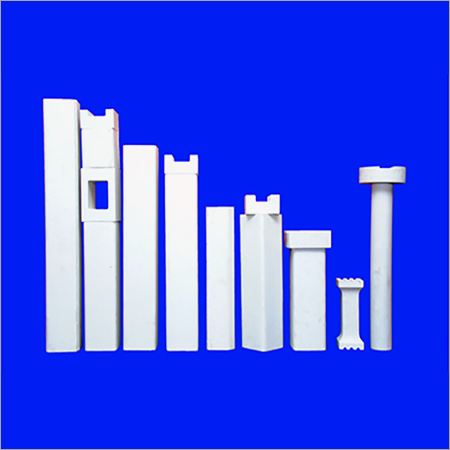

Corner Cut Batts

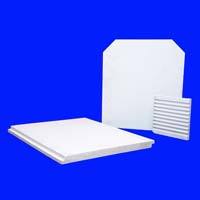

Corner Cut Batts Specification

- Operating Temperature

- Up to 230C

- Automation Grade

- Manual

- Surface Treatment

- Non-woven facing, Plain

- Used For

- Thermal and Acoustic Insulation

- Features

- Lightweight, Easy Installation, Moisture Resistant, Non-combustible

- Load Capacity

- Standard, as per design

- Material

- Glass Wool

- Style

- Corner Cut Batts

- Properties

- Thermal Insulation, Fire Retardant, Acoustic Insulation

- Capacity

- Variable thickness and sizes available

- Condition

- New

- Application

- Wall, Roof and Duct Insulation, Building Construction

Corner Cut Batts Trade Information

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Corner Cut Batts

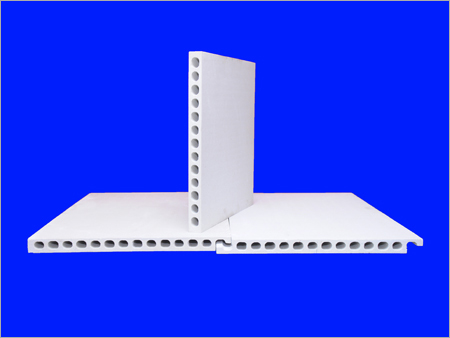

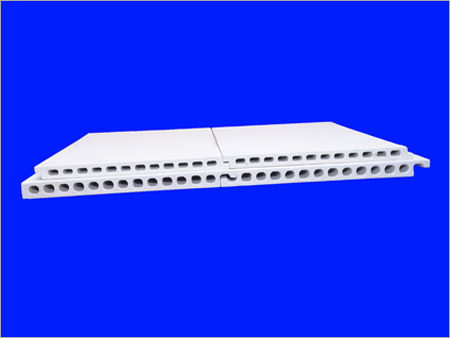

Versatile Application Across Industries

Corner Cut Batts are meticulously engineered for both plant-specific and general constructions, excelling in roof, wall, and duct insulation. Their distinctive design makes them ideal for use in industrial plants, commercial buildings, and residential projects. The products superior thermal and acoustic properties ensure energy efficiency and sound management, providing comfort and safety wherever installed. Perfect for new constructions or renovations, the batts can be tailored to diverse installation requirements as per the application site.

Certifications and Global Supply Network

Each batch of Corner Cut Batts comes with certifications such as IS and ASTM compliance. Our main export markets span Europe, the Middle East, Africa, and Asia, ensuring global availability. With flexible proposal amounts and transparent goods transport charges, we guarantee timely delivery and reliable supply. Thanks to substantial supply ability, we accommodate bulk and customized orders efficiently, securing a steady flow for builders and manufacturers worldwide.

FAQs of Corner Cut Batts:

Q: How are Corner Cut Batts installed for optimal performance?

A: Corner Cut Batts can be installed using a press fit method, mechanical fasteners, or suitable adhesives, allowing for seamless integration into walls, roofs, or ducts based on your construction needs.Q: What benefits do Corner Cut Batts offer in building construction?

A: These batts provide remarkable thermal insulation, fire retardance, and acoustic control, enhancing energy efficiency and safety in various applications, from commercial spaces to residential and industrial environments.Q: Where can Corner Cut Batts be used most effectively?

A: They are most effective in wall, roof, and duct insulation cases across industrial plants, commercial complexes, and homes, supporting general and specific insulation requirements.Q: What is the process for customizing the size of Corner Cut Batts?

A: You can specify required lengths or widths during your order; the manufacturer will then provide batts cut to the exact dimensions that fit your unique installation scenarios.Q: When should you consider upgrading to these eco-friendly insulation solutions?

A: Upgrade to Corner Cut Batts during new construction or renovation projects, especially when fire safety, acoustic comfort, and environmental responsibility are top priorities.Q: How does the product handle moisture and high temperatures?

A: Corner Cut Batts absorb less than 1% moisture by volume and maintain structural integrity at operating temperatures up to 230C, making them reliable for long-term service.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Extruded Batts Category

Roof Supporting System

Minimum Order Quantity : 100

Surface Treatment : Galvanized

Style : Modular, Customized

Used For : Roof and Wall Support

Features : Easy Installation, Adjustable, High Load Bearing

Properties : Corrosion Resistant, High Strength

Refractory Collar

Minimum Order Quantity : 100

Surface Treatment : Natural finish or as requested

Style : Collar

Used For : Sealing, jointing, and insulating hightemperature pipes and ducting

Features : Easy installation, Durable, Resistant to high heat and corrosion

Properties : High thermal resistance, Abrasionresistant, Chemically inert

Ceramic Saggar Tray

Minimum Order Quantity : 100

Surface Treatment : Glazed or Unglazed Surface

Style : Rectangular

Used For : Supporting and Protecting Wares During Firing Process

Features : Refractory, Durable, Thermal Shock Resistant, High Mechanical Strength

Properties : High Thermal Stability, Chemically Inert

Saggar Trays

Minimum Order Quantity : 100

Surface Treatment : Glazed / Unglazed

Style : Rectangular Trays

Used For : Holding Ceramics During Firing

Features : Thermal Shock Resistant, High Mechanical Strength, Corrosion Proof

Properties : High Temperature Resistant, Nonreactive, Thermal Stability

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry