Perforated Batts

Perforated Batts Specification

- Load Capacity

- Designed for standard wall/ceiling mounting

- Features

- Lightweight, Easy Installation, Durable

- Operating Temperature

- Up to 750C

- Used For

- Noise Reduction, Thermal Insulation

- Surface Treatment

- Perforated Finish

- Automation Grade

- Manual

- Material

- Mineral Wool

- Style

- Perforated Batts

- Properties

- High Acoustic Absorption, Fire Resistant

- Capacity

- Custom sizes available

- Condition

- New

- Application

- Sound Proofing in Industrial and Commercial Spaces

- Thermal Conductivity

- Low (exact value varies as per grade)

- Shape

- Rectangular with perforations

- Edge Detail

- Straight cut edges

- Length/Width

- Customized as per requirement

- Color

- White

- Standard Thickness

- 25 mm, 38 mm, 50 mm (customizable)

- Density

- 220 kg/m³ (typical)

Perforated Batts Trade Information

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

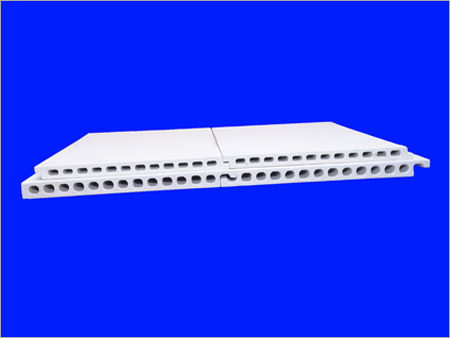

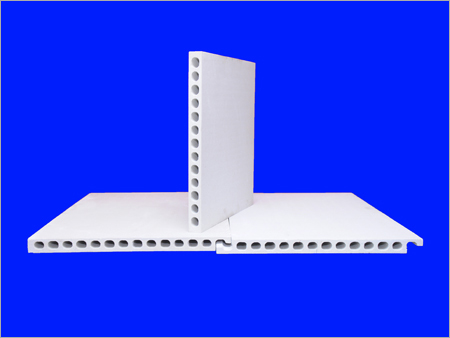

About Perforated Batts

Perforated Batts :-

Perforated Batts are available with high insulation properties and excellent temperature resistant design. They are developed with several holes punched at definite spaces to ensure to provide maximum performance. They are available with high-temperature resistant design with outstanding thermal shock stability. With maximum durability and efficacy, they have become the prime choice of different sectors from square tiles, sanitary wares, glazed mosaic tiles, western-style tiles, electronic ceramics to soft magnetic materials.

Features of Perforated Batts:

- Can easily tolerate high temperatures during firing

- No damage and deformation

- Durable and sturdy design for long lasting efficacy

- Easy to use and clean

High Acoustic and Thermal Performance

Perforated Batts are engineered for dual functionality, providing superior soundproofing and thermal insulation. The mineral wool core combined with a perforated outer finish ensures high acoustic absorption, making these batts particularly suitable for noisy environments such as factories, commercial spaces, or industrial facilities.

Customizable to Your Requirements

Available in standard thicknesses of 25 mm, 38 mm, and 50 mm, Perforated Batts can be tailored in length and width to fit unique architectural needs. This customization ensures seamless integration into various wall and ceiling designs, whether for new projects or renovation work.

Durable and Fire Resistant Solution

Manufactured from high-quality mineral wool, these batts are not only lightweight and robust but are designed to endure high temperatures up to 750C. The fire-resistant properties significantly enhance safety in industrial and commercial settings, adhering to stringent safety requirements.

FAQs of Perforated Batts:

Q: How are Perforated Batts installed in industrial or commercial spaces?

A: Perforated Batts are designed for manual installation onto walls or ceilings. Their lightweight nature and straight cut edges allow for quick mounting using standard fixing systems, making them easy to adapt to a variety of surfaces in both new constructions and retrofits.Q: What benefits do Perforated Batts offer for noise reduction?

A: Thanks to their high-density mineral wool composition and perforated finish, these batts provide excellent sound absorption. This significantly reduces noise transmission, making them ideal for applications where controlling sound levels is crucial, such as factories, offices, and commercial spaces.Q: Where can Perforated Batts be used effectively?

A: These panels are suitable for a broad range of industrial and commercial environments where noise reduction and thermal insulation are required. Common applications include machine rooms, auditoriums, office partitions, and any area that demands enhanced acoustic comfort and fire safety.Q: What is the process for ordering custom sizes or thicknesses of Perforated Batts?

A: Custom sizes and thicknesses can be ordered by specifying the required dimensions during the inquiry or purchase process. The manufacturer offers flexibility in length and width, and standard thickness options include 25 mm, 38 mm, and 50 mm, ensuring the product fits specific project needs.Q: When should Perforated Batts be chosen over other insulation materials?

A: These batts are ideal when the project requires both high acoustic absorption and fire resistance, in addition to effective thermal insulation. Their perforated design and customizable options set them apart from standard insulation panels, especially in environments with stringent safety and comfort standards.Q: How does the perforated finish impact the products performance?

A: The perforated surface enhances the acoustic absorption properties by allowing sound waves to penetrate the mineral wool core more efficiently. This feature is particularly beneficial in settings where ambient noise control is a priority.Q: What maintenance or care do Perforated Batts require once installed?

A: Perforated Batts are highly durable and require minimal maintenance. Regular inspections are advisable to ensure there is no visible damage or accumulation of dust on the panels, ensuring long-term performance and safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Extruded Batts Category

Roof Supporting System

Minimum Order Quantity : 100

Features : Easy Installation, Adjustable, High Load Bearing

Operating Temperature : 20C to 60C

Capacity : Up to 30 Tons

Used For : Roof and Wall Support

Properties : Corrosion Resistant, High Strength

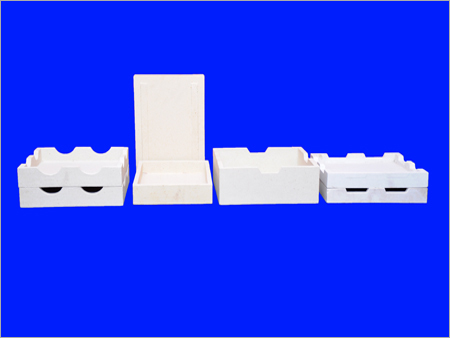

Saggar Tray With Cover

Minimum Order Quantity : 100

Features : Reusable, Durable, Thermal Stability, Corrosion Resistance

Operating Temperature : Up to 1700C

Capacity : 2 kg (Approx.)

Used For : Firing, Sintering, and Heat Treatment Processes

Properties : High Temperature Resistant, Thermal Shock Resistant

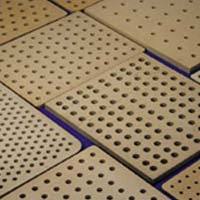

Saggar Trays

Minimum Order Quantity : 100

Features : Thermal Shock Resistant, High Mechanical Strength, Corrosion Proof

Operating Temperature : Up to 1700C

Capacity : Custom sizes available (Standard: 1 kg to 25 kg) per tray

Used For : Holding Ceramics During Firing

Properties : High Temperature Resistant, Nonreactive, Thermal Stability

Ceramic Saggar Tray

Minimum Order Quantity : 100

Features : Refractory, Durable, Thermal Shock Resistant, High Mechanical Strength

Operating Temperature : Up to 1600C

Capacity : Customizable (commonly 215 kg payload)

Used For : Supporting and Protecting Wares During Firing Process

Properties : High Thermal Stability, Chemically Inert

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry