Kiln Furniture

Kiln Furniture Specification

- Automation Grade

- Manual

- Features

- Durable, Corrosion Resistant, Even Heat Distribution, Lightweight

- Surface Treatment

- Smooth Glazed Finish

- Load Capacity

- High Load Bearing

- Used For

- Holding, Supporting and Separating Kiln Loads

- Operating Temperature

- Up to 1700C

- Material

- High Alumina Ceramic

- Style

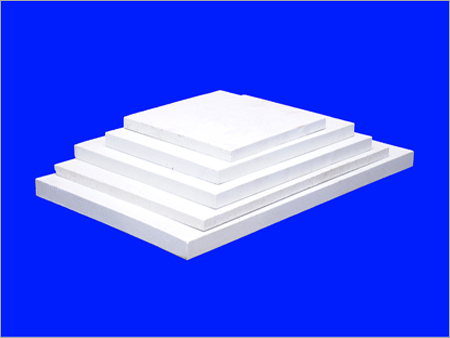

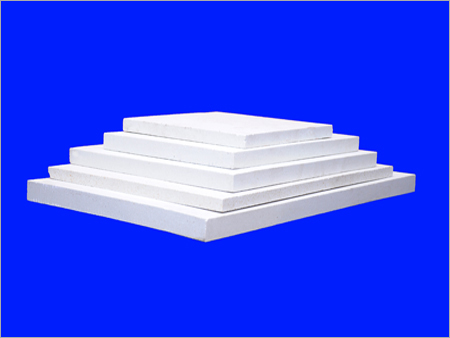

- Standard Rectangular Batts

- Properties

- High Strength, Thermal Shock Resistant

- Capacity

- Varies as per requirement

- Condition

- New

- Application

- Industrial Kilns and Furnaces

- Thickness Range

- 10 mm to 50 mm

- Manufacturing Process

- Isostatic pressing & slip casting

- Porosity

- <18%

- Density

- 2.4 2.6 g/cm

- Resistant to

- Thermal deformation, chemical attack

- Compliance

- Meets international standards for refractory products

- Usage Environment

- Oxidizing and neutral atmospheres

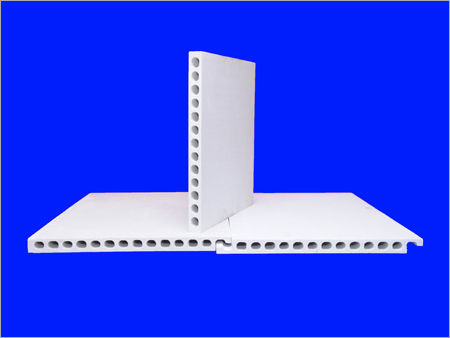

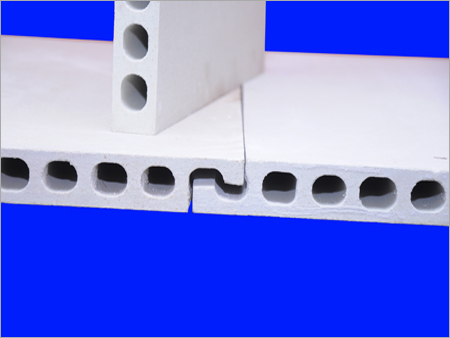

- Shape

- Plate, Batts, Setters, Beams, Props

- Color

- Off White

- Lifespan

- Long operational life, subject to usage conditions

- Compatibility

- Suitable for gas and electric kilns

- Standard Size

- Customized as per requirement

Kiln Furniture Trade Information

- FOB Port

- As per location

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Kiln Furniture

Adaptable Kiln Furniture for Diverse Industrial Uses

Our kiln furniture is designed for robust commercial usagesupporting, holding, and separating kiln loads throughout various industries. Crafted from premium high alumina ceramic, it resists thermal shock and chemical wear, while offering a smooth glazed surface for easy loading and cleaning. Its standard rectangular batts style and manual operation make it highly adaptable for different kiln environments, ensuring even heat distribution and lasting reliability during high-temperature processes up to 1700C.

Reliable Export, Quick Delivery & Affordable Pricing

We serve major export markets across Asia, Europe, and the Middle East, ensuring our kiln furniture reaches you with prompt transportation and sturdy packaging. Our list price competes at the lowest price point, making bulk industrial orders more accessible. Each shipment is carefully packed to prevent transit damage, and we offer flexible delivery schedules, streamlined to minimize downtime. With an established track record as reputable manufacturers, suppliers, and exporters from India, our service is tailored for seamless procurement.

FAQs of Kiln Furniture:

Q: How does kiln furniture resist thermal deformation and chemical attacks?

A: Our kiln furniture is constructed from high alumina ceramic, offering high strength and resilience. The materials unique structure, combined with advanced manufacturing processes like isostatic pressing and slip casting, provides resistance to high temperatures and harsh chemicals, ensuring durability in demanding industrial environments.Q: What types of kiln loads can these supports handle?

A: These kiln furniture pieces are designed for industrial use and can hold, support, and separate various loads, including ceramic products, refractories, or specialized ware. Their high load-bearing capacity and customizable dimensions make them suitable for a wide range of kiln applications.Q: Where can this kiln furniture be used?

A: Our kiln furniture is compatible with both gas and electric kilns operating in oxidizing and neutral atmospheres. It is suitable for use in industrial kilns and furnaces for ceramics, metallurgy, and materials processing industries.Q: What is the main benefit for commercial buyers?

A: Commercial buyers benefit from the kiln furnitures longevity, corrosion resistance, and even heat distribution, minimizing product defects and maximizing operational efficiency. The customizable size options and competitive pricing add further value for bulk purchasers.Q: How is the product delivered and packaged?

A: We ensure safe and prompt delivery by employing robust packaging methods that prevent breakage or scratches during transportation. Orders are shipped according to customer schedules, supporting both standard and urgent delivery requirements efficiently.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plain Batts Category

White Saggar Tray

Minimum Order Quantity : 1 Number

Used For : Holding ceramic wares during hightemperature firing in kiln

Operating Temperature : Up to 1350C

Properties : Thermal shock resistant, Acid and Alkali resistant

Material : Highquality Ceramic

Surface Treatment : Smooth glazed finish

Refractory Batts

Minimum Order Quantity : 100

Used For : Supporting and stacking ceramic products during firing

Operating Temperature : Up to 1700C

Properties : Thermal Shock Resistance, High Strength, Good Loadbearing Capacity

Material : High Alumina Refractory

Surface Treatment : Smooth Cast Finish

Extruded Batts

Minimum Order Quantity : 1 Number

Used For : Thermal insulation in high temperature processes

Operating Temperature : Up to 1450C

Properties : High temperature resistance, thermal shock stability, low thermal conductivity

Material : Ceramic Fibre

Surface Treatment : Smooth finish

Cordierite Batts

Minimum Order Quantity : 100

Used For : Supporting ceramic wares during firing

Operating Temperature : Up to 1320C

Properties : High thermal shock resistance, Low thermal expansion, Excellent mechanical strength

Material : Cordierite Ceramic

Surface Treatment : Uncoated / Natural finish

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry