Refractory Setters

Refractory Setters Specification

- Operating Temperature

- Up to 1700C

- Automation Grade

- Manual

- Features

- Corrosion Resistance, Dimensional Accuracy, Reusable

- Surface Treatment

- Smooth Finish

- Used For

- Supporting and holding ceramic ware during firing

- Load Capacity

- Optimized for stackable loads

- Material

- High Alumina Ceramic

- Style

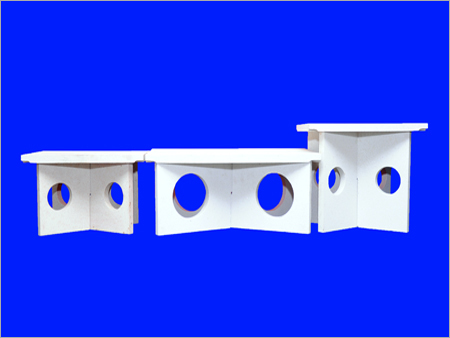

- Rectangular Setters

- Properties

- High Temperature Resistance, Thermal Shock Stability

- Capacity

- Standard sizes available as per requirements

- Condition

- New

- Application

- Kiln Furniture, Sintering Processes

Refractory Setters Trade Information

- Minimum Order Quantity

- 100 Number

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Refractory Setters

This Refractory Setters is designed to ensure to develop high quality stool in exact dimension and style according to the demand of the market. It is developed in porous / low density structure to make it ideal to limit its mechanical strength. It is reckoned as one of the most cost-effective setters for providing support for sintering, firing, as well as other heat-treatment processes. It can be used within the temperature range from 1000 to 1300oC.

Features of Stool Setter:

- Ensure to provide long-life setters for different heat treatment processes

- Can easily withstand working temperatures up to 1300oC (2400oF)

- Resistant to thermal shock cracking

- Very rapid heating as well as cooling rates

Exceptional Durability and Temperature Resistance

Constructed from premium high alumina ceramic, these refractory setters withstand extreme temperatures up to 1700C, making them ideal for kiln furniture and sintering processes. Their low water absorption and high compressive strength ensure longevity, even in repetitive firing cycles, while maintaining dimensional accuracy and structural integrity.

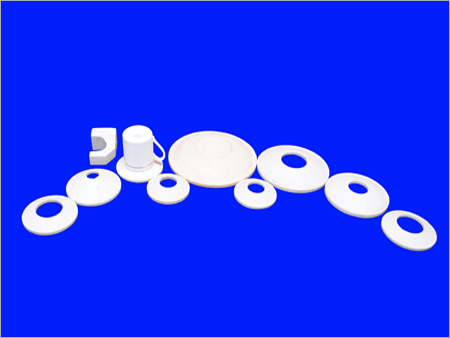

Adaptable Shapes and Reliable Support

Available in flat, rectangular, or customized configurations with straight or chamfered edges, our setters provide stable and efficient support for a variety of ceramic ware. Their optimized load capacity allows for secure stacking and flexible usage in numerous firing applications, enhancing operational efficiency in manufacturing setups.

FAQs of Refractory Setters:

Q: How can Refractory Setters be used during ceramic firing processes?

A: Refractory Setters are used to support and hold ceramic ware within kilns during firing cycles. Their excellent thermal shock stability and strength ensure that ceramic items remain stable and resist warping or cracking, contributing to high-quality fired products.Q: What are the benefits of choosing high alumina ceramic Refractory Setters over alternative materials?

A: High alumina ceramic offers superior temperature resistance (up to 1700C), notable strength, chemical inertness, and exceptional durability. This results in prolonged usage life, reduced replacement frequency, and minimal contamination of ceramic goods during firing.Q: When should I opt for custom shapes or standard sizes for these setters?

A: Select standard sizes if your kiln or firing processes accommodate common dimensions; choose custom shapes and thicknesses when your ware or setup requires precise fit or specialized support, ensuring optimal performance and efficiency.Q: Where are these setters best applied within the manufacturing process?

A: These setters are most effective as kiln furniture during all sintering processes, especially where repeated heating cycles and reliable ware support are critical, such as in ceramic tile, pottery, and technical ceramics production environments.Q: What is the packaging and delivery process for Refractory Setters?

A: Setters are securely packed in robust wooden boxes or cartons to prevent damage during transport. Being exporters, manufacturers, and suppliers in India, we offer prompt delivery across local and international destinations, tailored to client specifications.Q: How does low porosity and water absorption benefit setter performance?

A: Low porosity (<20%) and water absorption (1%) significantly reduce the risk of thermal shock and chemical attack, enhancing setter stability and extending their lifespan during intensive firing cycles.Q: Can these setters be reused for multiple firing cycles?

A: Absolutely. Thanks to their high temperature resistance, corrosion resistance, and structural strength, these setters are engineered for protracted usage across numerous cycles, optimizing operational costs and resource efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Profile Setters Category

Refractory Material

Minimum Order Quantity : 100

Operating Temperature : Up to 1700C

Pressure Ratings : Up to 25 MPa (depends on specific material)

Condition : New

Capacity : Customized as per requirement

Application : Furnaces, Kilns, Boilers, Incinerators

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry