Refractory Material

Refractory Material Specification

- Operating Temperature

- Up to 1700C

- Load Capacity

- Varies with type, up to several tons

- Features

- Durable, Corrosion resistant, Low thermal conductivity

- Automation Grade

- Manual

- Phase

- Solid

- Pressure Ratings

- Up to 25 MPa (depends on specific material)

- Surface Treatment

- Uncoated/Cast

- Used For

- Heat insulation, Lining of high-temperature structures

- Material

- Alumina, Silica, Magnesite

- Style

- Block/Brick

- Properties

- High temperature resistance, Chemical stability, Thermal shock resistance

- Capacity

- Customized as per requirement

- Condition

- New

- Application

- Furnaces, Kilns, Boilers, Incinerators

Refractory Material Trade Information

- Minimum Order Quantity

- 100 Number

- Supply Ability

- 100 Per Month

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard & Crate Packaging.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Refractory Material

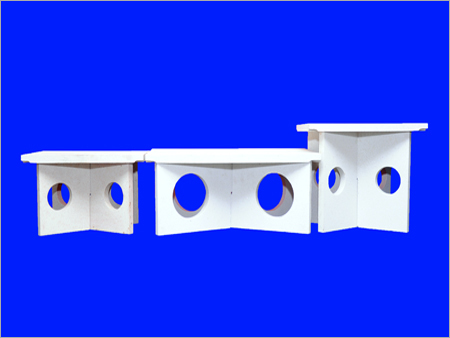

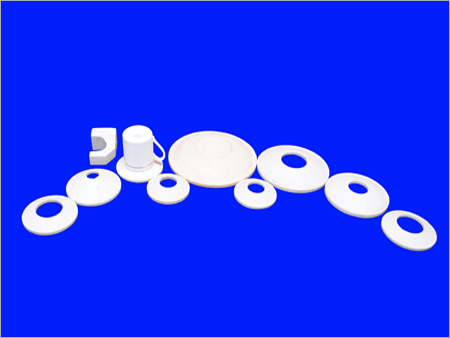

Refractory Material are special items in the domain of ceramic tableware industry. They are designed and shaped with the under surface of plates as well as dishes to ensure to provide maximum strength. The main function of these setters is to serve the support ware. In addition, they also ensure to maintain the shape of the support ware in the kiln during firing. They are designed to maintain the shape of roundness of the rim of cups as well as other circular small hollow ware.

Features of Cup Setters:

- Contain small parts as well as powders in the kiln during firing

- Can be easily stacked to utilize minimum kiln space

- Available in various materials to suit different temperature cycles

- Robust construction to easily withstand high temperature and pressure

Optimized for Extreme Environments

Engineered for applications demanding resilience to heat and chemical exposure, these refractory materials withstand operating temperatures up to 1700C and loads of several tons. Their robust structure ensures reliability and safety even under harsh industrial conditions, making them a preferred choice for furnace and kiln linings.

Versatile Customization and Application

Available in various shapesstandard rectangular blocks or custom designsthese refractory products adapt seamlessly to different structural requirements. Whether insulating a boiler or lining a complex-incinerator, their tailored capacity and manual installation process maximize compatibility and effectiveness for unique project needs.

FAQs of Refractory Material:

Q: How are refractory materials with these specifications typically used in industrial applications?

A: These refractory materials are installed as lining inside furnaces, boilers, kilns, and incinerators to provide heat insulation and protect structural walls from high temperatures and chemical attack, ensuring operational safety and energy efficiency.Q: What benefits does the high alumina content offer to these refractories?

A: The high alumina content significantly enhances thermal resistance, mechanical strength, and chemical stability, allowing the blocks or bricks to maintain integrity and performance under temperatures up to 1700C and in corrosive environments.Q: When should custom-shaped refractories be considered over standard shapes?

A: Custom-shaped refractories are recommended when the project requires fitting irregular or uniquely designed high-temperature structures where standard rectangular blocks are unsuitable, ensuring optimal coverage and protection.Q: Where should these refractories be stored to ensure maximum shelf life?

A: For best results, store the refractory materials in a dry environment, off the ground, preferably on a wooden pallet or in a carton box, away from moisture to maintain their long shelf life and preserve their physical properties.Q: What is the typical process for installing these refractory blocks or bricks?

A: Installation is typically manual, involving the precise arrangement of blocks or bricks according to the design specifications, sometimes using heat-resistant mortar, to ensure tight joints and structural integrity within furnaces or kilns.Q: How does porosity and water absorption impact the performance of these refractories?

A: Porosity (2226%) and water absorption (1820%) affect insulation properties and thermal shock resistance; these optimized values help balance energy efficiency with durability under rapid temperature changes.Q: What key features set these refractory materials apart from alternatives?

A: These materials feature low thermal conductivity, high compressive strength, chemical stability, and excellent corrosion resistance, providing long-term durability and superior performance in demanding thermal environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Profile Setters Category

Refractory Setters

Minimum Order Quantity : 100

Properties : High Temperature Resistance, Thermal Shock Stability

Application : Kiln Furniture, Sintering Processes

Used For : Supporting and holding ceramic ware during firing

Style : Rectangular Setters

Surface Treatment : Smooth Finish

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry