Kiln Furniture

Kiln Furniture Specification

- Automation Grade

- Manual Handling

- Power Source

- N/A (Non-Electrical)

- Pressure Ratings

- Atmospheric

- Voltage

- N/A (Non-Electrical)

- Load Capacity

- Depend on Design, up to 500 kg per set

- Surface Treatment

- Smooth Glazed or Unglazed

- Features

- Long Service Life, Lightweight, High Mechanical Strength

- Operating Temperature

- Up to 1700C

- Phase

- N/A (Non-Electrical)

- Used For

- Ceramic, Pottery, and Refractory Firing

- Material

- High Alumina Ceramic

- Style

- Rectangular Plates & Props

- Properties

- High Thermal Shock Resistance, Low Thermal Expansion

- Capacity

- Customizable as per requirement

- Power

- N/A (Passive Kiln Accessory)

- Condition

- New

- Application

- Support Shelves and Wares during Firing

Kiln Furniture Trade Information

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Kiln Furniture

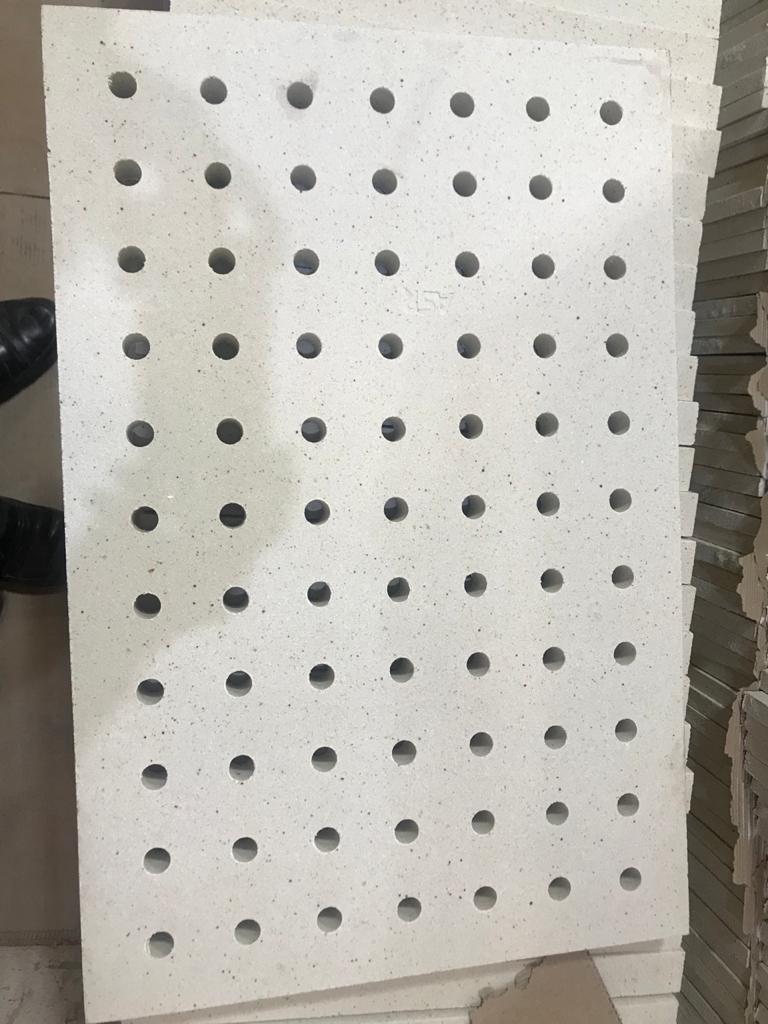

Kiln Furniture

Refractory products used by the ceramics industry to support wares during firing are generally referred to as kiln furniture. The rigorous conditions encountered in this application demand a material that resists deformation or mechanical failure during repeated heating and cooling cycles.

Kiln furniture pieces are damaged by cracking, bending, the accumulation of dirt and glaze or surface degradation due to oxidation or some other form of chemical attack or contamination.

For service temperatures up to 1300 deg C the most popular type of refractory material contains the mineral cordierite, a magnesium aluminum silicate with a very low thermal expansion coefficient, rendering it highly resistant to thermal shock. Most commercial cordierite kiln furniture bodies are formulated to produce about 50% cordierite, the remainder comprising mullite (Molochite-based or chamotte-based) and amorphous material.

Durable High Alumina Construction

Crafted using advanced high-temperature sintering, our kiln furniture utilizes high alumina ceramic to provide outstanding mechanical strength and thermal stability. This makes them highly suitable for frequent kiln cycling in both oxidizing and reducing atmospheres. Their low porosity and exceptional thermal shock resistance reduce the risk of cracking or deformation, ensuring extended performance even under intense firing conditions.

Custom Solutions for Versatile Kiln Applications

Available in a range of shapes, including rectangular plates and support props, our kiln furniture can be tailored to precise client requirements in size, thickness, and load capacity. This versatility makes them fit seamlessly into diverse kiln designswhether for ceramic studios or industrial-scale refractory operations. The smooth glazed or unglazed surface treatment ensures easy handling and minimal contamination during use.

Enhanced Performance and Longevity

Engineered to outperform standard kiln furniture, our products offer longer service life due to their high mechanical strength and low thermal expansion. Able to support heavy loads (up to 500 kg per set) at temperatures up to 1700C, they maintain their integrity through repeated firing cycles. Compliance with industrial manufacturing norms assures quality and reliability for all clients.

FAQs of Kiln Furniture:

Q: How is high alumina kiln furniture manufactured to ensure durability?

A: Our kiln furniture is produced through a high-temperature sintering process using premium high alumina ceramic. This technique ensures low porosity, excellent thermal shock resistance, and high mechanical strength, providing durability and extended service life even under harsh firing conditions.Q: What are the main benefits of using your kiln furniture for ceramic and refractory firing?

A: Key advantages include extended product life, high load-bearing capacity (up to 500 kg per set), superior resistance to thermal shock, and minimal thermal expansion. These features help prevent distortion, cracking, and premature wear, improving firing consistency and reducing maintenance costs.Q: Can the size and shape of kiln furniture be customized for different kiln types?

A: Absolutely. We offer full customization in terms of size, thickness, and design to meet specific kiln requirements. Available shapes include various rectangular plates and props to support a wide variety of ware and kiln configurations.Q: When should kiln furniture be replaced during regular operations?

A: Although our kiln furniture is designed for an extended service life, periodic inspection after each firing cycle is recommended. Replacement is necessary if visible cracking, significant warping, or notable material degradation occurs, especially after prolonged high-temperature use.Q: Where are your kiln furniture products typically used?

A: Our kiln furniture finds application across ceramics studios, pottery workshops, and industrial refractory production throughout India, supporting shelves and products during firing without contaminating the ware.Q: What process should be followed for proper usage and maintenance?

A: Before each firing, ensure that kiln furniture surfaces are clean and free of debris. When loading, distribute weight evenly to prevent warping. Handle with care during placement and extraction, and store in a dry, clean area to preserve surface integrity.Q: What distinguishes your kiln furniture from standard alternatives?

A: Compared to conventional kiln furniture, our high-alumina range provides longer operational life, better mechanical strength, lighter weight for easier handling, and higher resistance to thermal cycling. Compliance with industry norms ensures consistent quality and performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry